1. High Thermal Stability: Alumina Cylindrical Crucible can withstand extremely high temperatures, often exceeding 1700°C, without compromising their structural integrity. This makes them suitable for use in processes requiring prolonged exposure to high temperatures.

2. Chemical Resistance:Alumina Cylindrical Crucible exhibit excellent resistance to a wide range of chemicals, including acids and alkalis, ensuring that they do not react with the substances they contain. This property is crucial for maintaining the purity of the materials being processed.

3. Mechanical Strength: The robust nature of alumina ensures that the Alumina Cylindrical Crucible can endure mechanical stress and thermal shock, reducing the risk of cracking or breaking during rapid temperature changes.

4. Low Thermal Conductivity: Alumina's low thermal conductivity helps in minimizing heat loss, making these Alumina Cylindrical Crucible efficient for energy-intensive processes.

Send Email

More

Menu

- Home

- Products

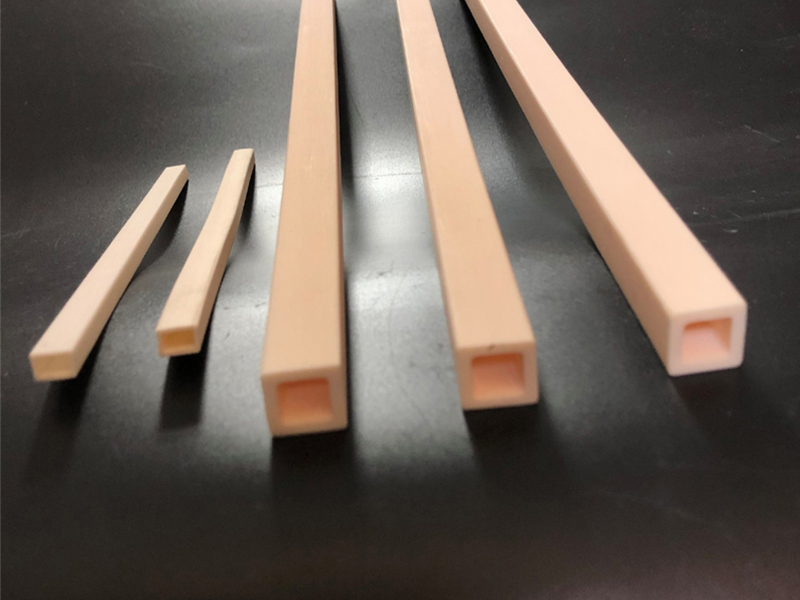

- Alumina Ceramic Tube

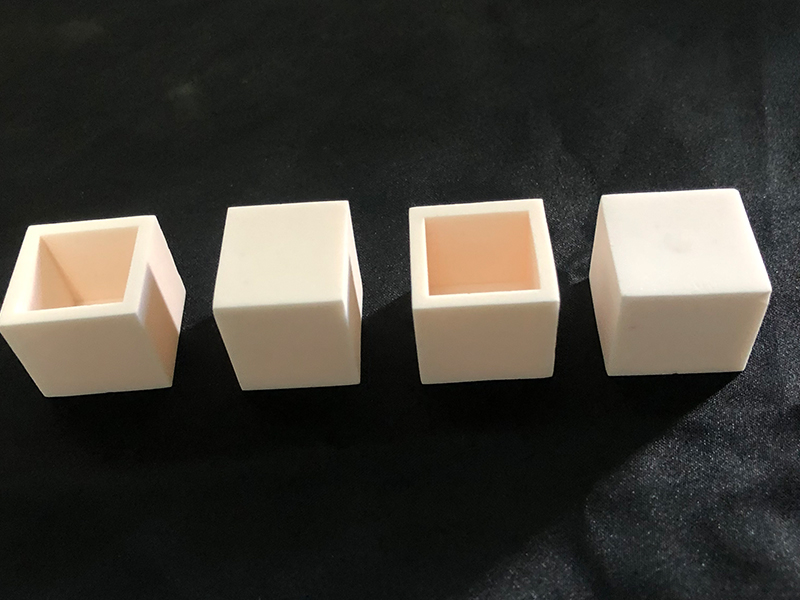

- Alumina Ceramic Crucible

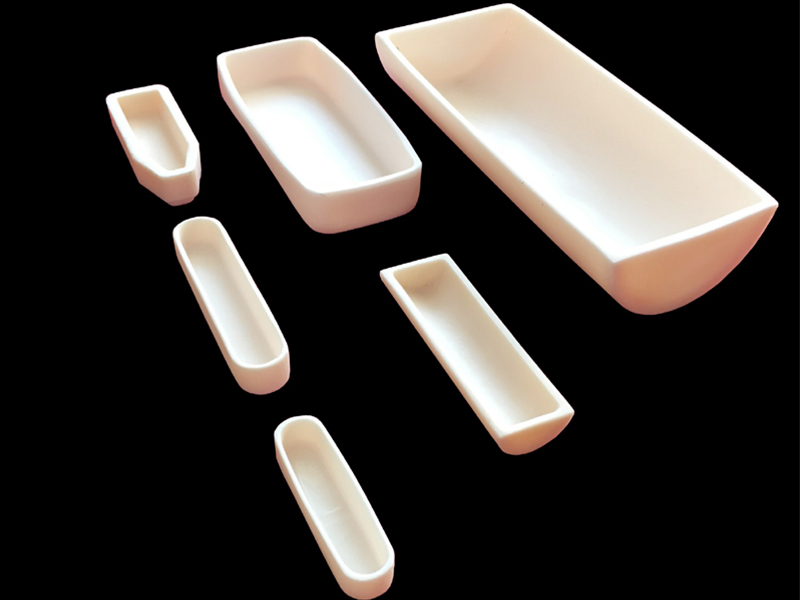

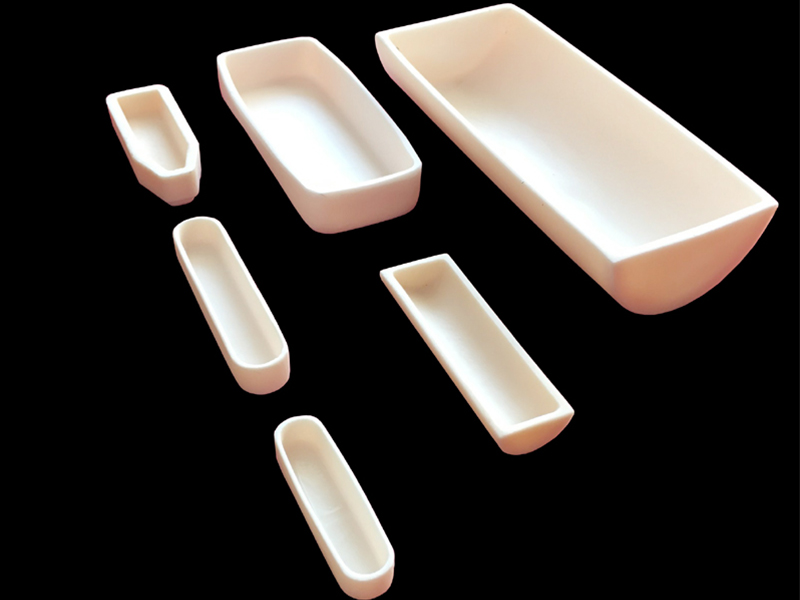

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search