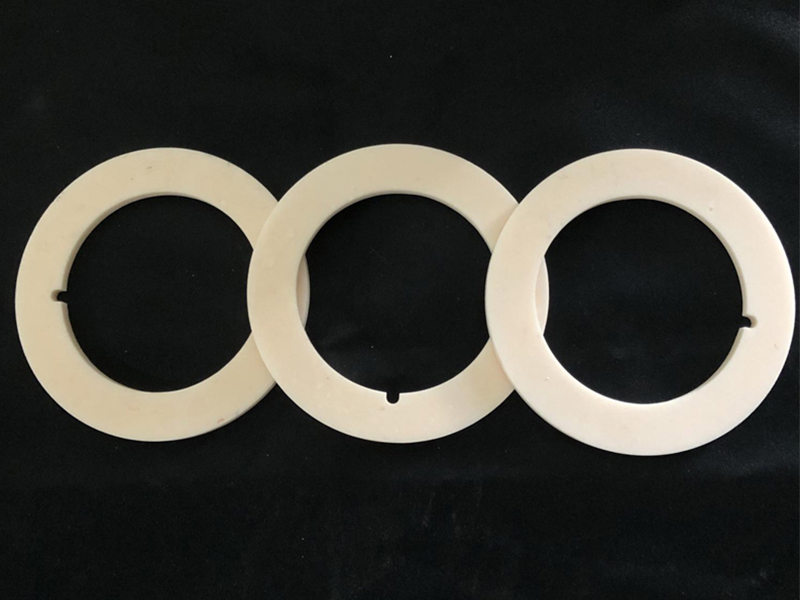

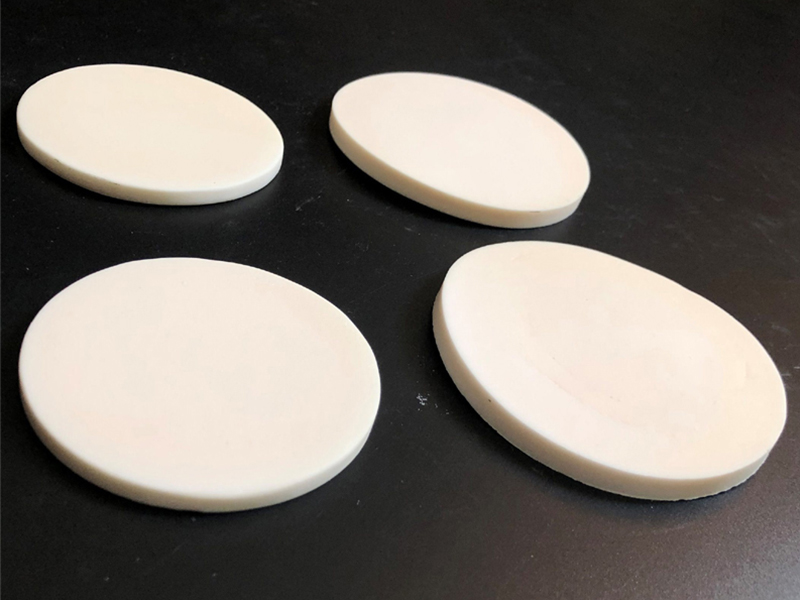

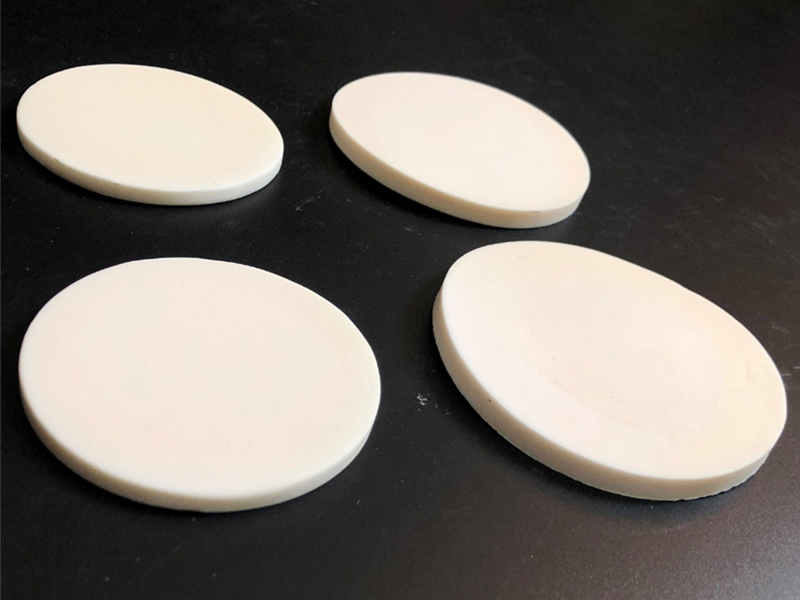

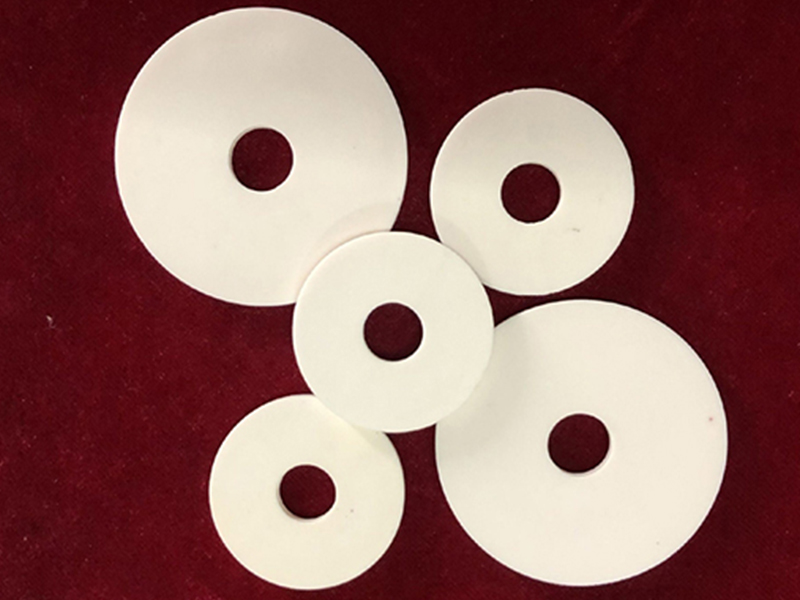

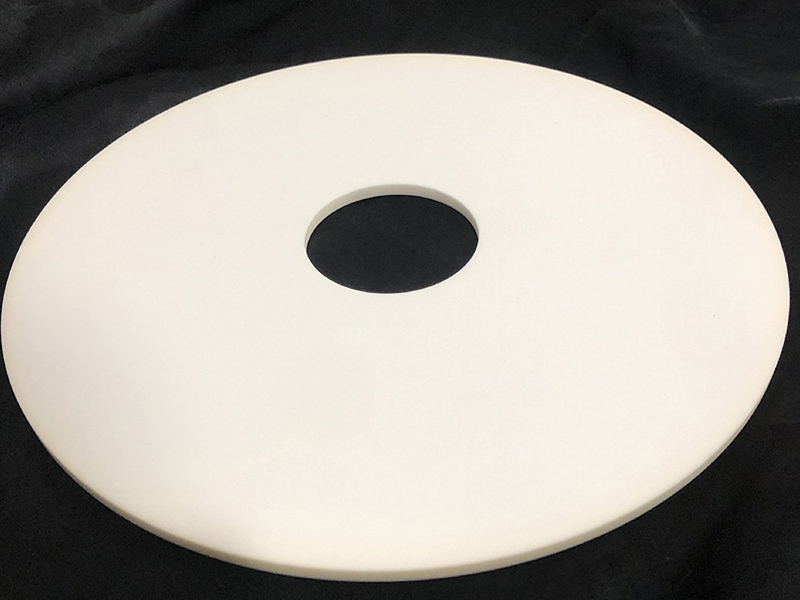

1. Alumina ceramic ring slice Large hardness

Alumina ceramic ring slice Measured by professional research institutes, its Loss hardness is HRA80-90, second only to diamond, and Alumina ceramic ring slice wear resistance far exceeds wear-resistant steel and stainless steel.

2. Alumina ceramic ring slice good wear resistance

Alumina ceramic ring slice its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron.

3. Lightweight

Its density is 3.5g/cm3, which is only half of steel, which can greatly reduce the equipment load.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search