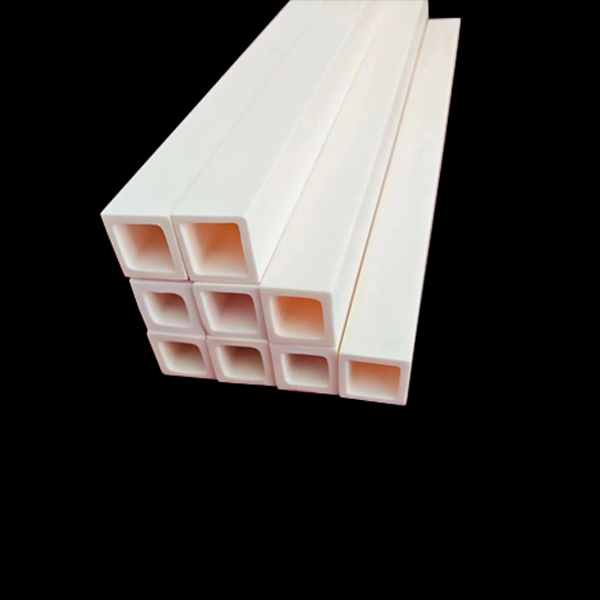

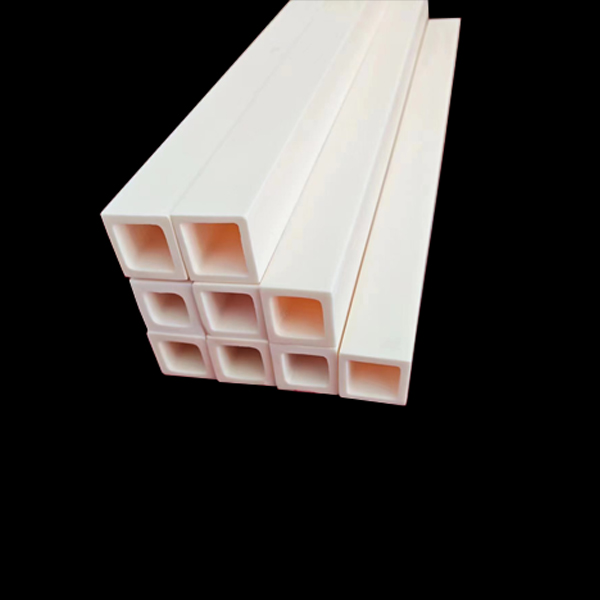

Alumina Ceramic Tube Square

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000*10,000/month(Looking for distributors)

1. The high mechanical strength, wear resistance, corrosion resistance, and thermal shock resistance of alumina ceramic tube square ensure an extended service life.

2. The superior electrical insulation performance of alumina ceramic tube square makes them indispensable in electrical applications, preventing short circuits and electrical faults.

3. The chemical inertness of alumina ceramic tube square enables their safe use in corrosive chemical environments, maintaining the integrity of the product.

4. Alumina ceramic tube square have significant heat resistance and maintain structural integrity at high temperatures.

Alumina Ceramic Tube Square

My factory looking for distributors.

Square tube size: 25*25*400mm

Advantages of Alumina Ceramic Tube Square

1. The high mechanical strength, wear resistance, corrosion resistance, and thermal shock resistance of alumina ceramic tube square ensure an extended service life.

2. The superior electrical insulation performance of alumina ceramic tube square makes them indispensable in electrical applications, preventing short circuits and electrical faults.

3. The chemical inertness of alumina ceramic tube square enables their safe use in corrosive chemical environments, maintaining the integrity of the product.

4. Alumina ceramic tube square have significant heat resistance and maintain structural integrity at high temperatures.

5. The precise size and customizable shape of alumina ceramic tube square allow for tailored solutions that seamlessly integrate into different systems.

6. The lightweight design of alumina ceramic tube square facilitates operation and installation, simplifying the operation process.

Application of Alumina Ceramic Tube Square

1. Alumina ceramic tube squares are versatile components widely utilized across various industries due to their exceptional properties and diverse applications. These squares, composed primarily of alumina (Al2O3), exhibit high thermal conductivity, excellent electrical insulation, superior mechanical strength, and remarkable resistance to corrosion and wear.

2. Alumina ceramic tube squares superb electrical insulation properties make them ideal for use in insulating substrates, connectors, and components within electronic systems.

3. Alumina ceramic tube squares ability to withstand extreme temperatures makes them suitable for applications such as kiln furniture, furnace linings, and thermal barriers.

4. Alumina ceramic tube squares exceptional resistance to thermal shock and mechanical stress ensures reliability and durability in aerospace and automotive systems operating under harsh conditions.

5. Alumina ceramic tube squares are employed in various applications, including biomedical implants and laboratory equipment. Their biocompatibility, inertness, and resistance to chemical corrosion make them suitable for use in medical devices such as prosthetic implants, dental implants, and surgical instruments.

6. Alumina ceramic tube squares find niche applications in the field of renewable energy, particularly in solar energy systems.

7. Alumina ceramic tube squares are indispensable components with diverse applications across various industries.

Product information

▪ The alumina furnace tube max diameter can get 130 mm with length 1800 mm.

▪ Custom shape like the circular tube, square tube, horseshoe tube, outer wire tube.

▪ Full of stock in warehouse

▪ Without any burrs and sharp corners

▪ Can do the ground finish with the serious tolerance processing

▪ Can provide the free sample for testing qualuty first

Alumina Tube(open both ends)(slip casting) Specification Table

Number | SPEC: OD x ID |

LENGTH MM |

Number | SPEC: OD x ID |

LENGTH MM | ||

INCH | MM | INCH | MM | ||||

1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 |

≤1800 |

2 | 0.236x0.157 | 6x4 |

≤1300 | 33 | 1.181x0.827 | 30x21 | |

3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 | ||

4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 | ||

5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 | ||

6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 | ||

7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 | ||

8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 | ||

9 | 0.354x0.236 | 9x6 |

≤1600 | 40 | 1.654x1.339 | 42x34 | |

10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 | ||

11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 | ||

12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 | ||

13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 | ||

14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 | ||

15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 | ||

16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 | ||

17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 | ||

18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 | ||

19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 | ||

20 | 0.591x0.394 | 15x10 |

≤1800 | 51 | 2.750x2.500 | 69.9x63.5 | |

21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 | ||

22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 | ||

23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 | ||

24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 | ||

25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 |

≤1600 | |

26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 | ||

27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 | ||

28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 | ||

29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 |

≤1500 | |

30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 | ||

31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 | ||

Insulation tube (extrusion) Specification Table

Number | 1 Bore tube SPEC: OD x ID | LENGTH MM | |

INCH | MM | ||

1 | 0.031x0.011 | 0.8x0.3 |

≤18500 |

2 | 0.039x0.019 | 1x0.5 | |

3 | 0.059x0.024 | 1.5x0.6 | |

4 | 0.079x0.039 | 2x1 | |

5 | 0.100x0.050 | 2.5x1.3 | |

6 | 0.118x0.059 | 3x1.5 | |

7 | 0.118x0.079 | 3x2 | |

8 | 0.125x0.063 | 3.2x1.6 | |

9 | 0.157x0.079 | 4x2 | |

10 | 0.197x0.118 | 5x3 | |

11 | 0.236x0.118 | 6x3 | |

12 | 0.236x0.157 | 6x4 | |

13 | 0.250x0.125 | 6.4x3.2 | |

14 | 0.250x0.157 | 6.4x4 | |

15 | 0.250x0.188 | 6.4x4.8 | |

16 | 0.276x0.197 | 7x5 | |

17 | 0.315x0.197 | 8x5 | |

18 | 0.354x0.236 | 9x6 | |

19 | 0.374x0.250 | 9.5x6.35 | |

20 | 0.394x0.236 | 10x6 | |

21 | 0.433x0.276 | 11x7 | |

22 | 0.472x0.315 | 12x8 | |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of ceramic tube, such as shape, dimension, quantity, application etc.

Q2. What is alumina ceramic used for?

A:Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves. Aluminum oxide ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

Q3. Is alumina ceramic safe?

A:Alumina ceramic, composed mainly of aluminum oxide (Al2O3), is widely regarded as safe for various applications due to its biocompatibility, thermal resistance, and electrical insulation properties. Used in medical implants and dental applications, it is well-tolerated by the body.

Q4. Can alumina ceramic furnace tubes be reused after use?

A:Yes, alumina ceramic furnace tubes can be reused after use, provided they are undamaged and free from contamination. Proper cleaning and inspection are necessary to ensure their suitability for subsequent applications.

Q5. Are alumina ceramic furnace tubes suitable for high-pressure applications?

A:Yes, alumina ceramic furnace tubes can be used in high-pressure applications. Their excellent mechanical strength and resistance to thermal and chemical stresses make them suitable for demanding conditions.

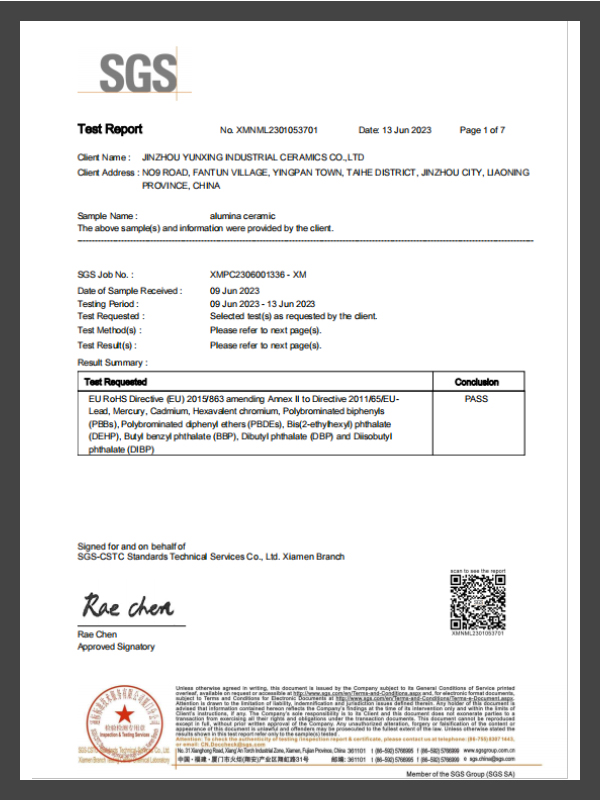

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.