Alumina Tubes

- yunxing

- china

- According to the quantity ordered

- 2000-5000/month(Looking for distributors)

1.High Mechanical Strength: Our Alumina Tubes exhibit remarkable mechanical strength, ensuring durability and reliability in the face of demanding industrial environments. Constructed with precision, these tubes offer exceptional stability and robustness, enabling seamless operations even under extreme conditions.

2.Optimal Electrical Insulation: With high resistivity and excellent electrical insulation properties, Alumina Tubes guarantee a safe and reliable electrical infrastructure. Your equipment will be safeguarded against electrical currents, ensuring uninterrupted power supply and protecting your investments from potential damages.

3.High Temperature Resistance: Industries often encounter extreme temperatures, and our Alumina Tubes are designed to withstand the heat. With an impressive melting point and remarkable resistance to temperature variations, they ensure that your operations run smoothly, even in the harshest environments.

Alumina Tubes

Today, we introduce the incomparable "Alumina Tube," a ceramic masterpiece that offers exceptional mechanical strength, electrical insulation, temperature resistance, and chemical stability. Crafted to perfection by leading manufacturers, our Alumina Tubes are here to redefine the standards of industrial ceramics.

Advantages of Alumina tubes

1.High Mechanical Strength: Our Alumina Tubes exhibit remarkable mechanical strength, ensuring durability and reliability in the face of demanding industrial environments. Constructed with precision, these tubes offer exceptional stability and robustness, enabling seamless operations even under extreme conditions.

2.Optimal Electrical Insulation: With high resistivity and excellent electrical insulation properties, Alumina Tubes guarantee a safe and reliable electrical infrastructure. Your equipment will be safeguarded against electrical currents, ensuring uninterrupted power supply and protecting your investments from potential damages.

3.High Temperature Resistance: Industries often encounter extreme temperatures, and our Alumina Tubes are designed to withstand the heat. With an impressive melting point and remarkable resistance to temperature variations, they ensure that your operations run smoothly, even in the harshest environments.

4.Chemical Resistance and Corrosion Protection:Alumina Tubes provide an impenetrable shield against chemical reactions, demonstrating outstanding resistance to various corrosive substances. This exceptional chemical stability ensures the longevity of your equipment, minimizing maintenance costs, and maximizing production efficiency.

5.Excellent Optical Properties: In addition to its exceptional mechanical and chemical properties, Alumina Tubes also provide outstanding optical clarity. The crystal-clear surfaces of these tubes allow for enhanced visibility and accuracy, making them ideal for diverse applications in the optical industry.

6.Ion Conductivity and Industrial Applications: The superior Alumina Tubes boast excellent ion conductivity, making them an indispensable asset in various industrial processes. From advanced semiconductor manufacturing to smart grid technologies, these tubes contribute to the progress and advancement of multiple sectors, paving the way for innovation and efficiency.

Application of Alumina tubes

1. Furnace work tubes

2. Kiln furniture, components & accessories

3. Thermocouple protection tubes

4.Heater Support Elements

5. High Temperature Electrical Insulators

6. Extreme temperature measurement components

7.Ceramic Laser components

8. High voltage electrical insulators

Alumina Tube(open both ends)(slip casting) Specification Table

Number | SPEC: OD x ID |

LENGTH MM |

Number | SPEC: OD x ID |

LENGTH MM | ||

INCH | MM | INCH | MM | ||||

1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 |

≤1800 |

2 | 0.236x0.157 | 6x4 |

≤1300 | 33 | 1.181x0.827 | 30x21 | |

3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 | ||

4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 | ||

5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 | ||

6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 | ||

7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 | ||

8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 | ||

9 | 0.354x0.236 | 9x6 |

≤1600 | 40 | 1.654x1.339 | 42x34 | |

10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 | ||

11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 | ||

12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 | ||

13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 | ||

14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 | ||

15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 | ||

16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 | ||

17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 | ||

18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 | ||

19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 | ||

20 | 0.591x0.394 | 15x10 |

≤1800 | 51 | 2.750x2.500 | 69.9x63.5 | |

21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 | ||

22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 | ||

23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 | ||

24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 | ||

25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 |

≤1600 | |

26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 | ||

27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 | ||

28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 | ||

29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 |

≤1500 | |

30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 | ||

31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 | ||

Insulation tube (extrusion) Specification Table

Number | 1 Bore tube SPEC: OD x ID | LENGTH MM | |

INCH | MM | ||

1 | 0.031x0.011 | 0.8x0.3 |

≤18500 |

2 | 0.039x0.019 | 1x0.5 | |

3 | 0.059x0.024 | 1.5x0.6 | |

4 | 0.079x0.039 | 2x1 | |

5 | 0.100x0.050 | 2.5x1.3 | |

6 | 0.118x0.059 | 3x1.5 | |

7 | 0.118x0.079 | 3x2 | |

8 | 0.125x0.063 | 3.2x1.6 | |

9 | 0.157x0.079 | 4x2 | |

10 | 0.197x0.118 | 5x3 | |

11 | 0.236x0.118 | 6x3 | |

12 | 0.236x0.157 | 6x4 | |

13 | 0.250x0.125 | 6.4x3.2 | |

14 | 0.250x0.157 | 6.4x4 | |

15 | 0.250x0.188 | 6.4x4.8 | |

16 | 0.276x0.197 | 7x5 | |

17 | 0.315x0.197 | 8x5 | |

18 | 0.354x0.236 | 9x6 | |

19 | 0.374x0.250 | 9.5x6.35 | |

20 | 0.394x0.236 | 10x6 | |

21 | 0.433x0.276 | 11x7 | |

22 | 0.472x0.315 | 12x8 | |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

Q1. What information should we supply to get a quote?

A: Please offer the specification of ceramic tube, such as shape, dimension, quantity, application etc.

Q2. Can alumina ceramic furnace tubes withstand rapid temperature changes?

A: Alumina ceramic furnace tubes exhibit good thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or breaking. However, it's essential to choose a tube with suitable thermal shock resistance for specific application requirements.

Q3. Can alumina ceramic furnace tubes be custom-designed for specific applications?

A: Yes, many suppliers offer customization options for alumina ceramic furnace tubes. Customization can include adjustments to size, shape, and additional features to meet the specific needs of your application.

Q4. How long do alumina ceramic furnace tubes typically last?

TA: he lifespan of alumina ceramic furnace tubes can vary depending on factors such as application conditions, operating temperatures, and maintenance practices. With proper care and usage, these tubes can last several years, providing reliable performance.

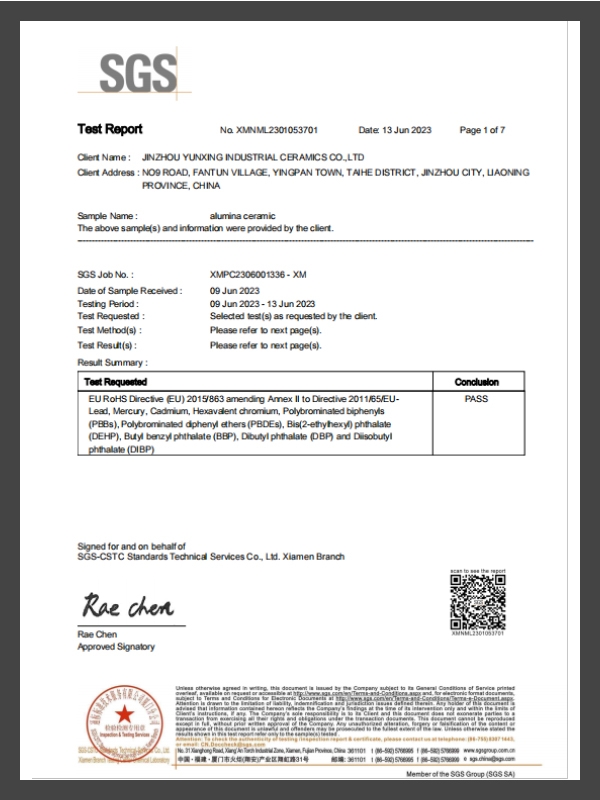

Certificate

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.