1. High Thermal Stability: Alumina crucibles can withstand temperatures up to 1700°C, making them suitable for applications in extreme heat.

2. Chemical Resistance: Alumina crucibles are resistant to most acids, alkalis, and other corrosive substances, ensuring longevity in harsh environments.

3. Durability: Alumina crucibles hardness and mechanical strength provide excellent wear resistance.

4. Purity: High-purity alumina minimizes contamination, making these crucibles perfect for analytical and laboratory applications.

5. Cost-Effective: Given their longevity and durability, alumina crucibles offer great value over time.

Send Email

More

Menu

- Home

- Products

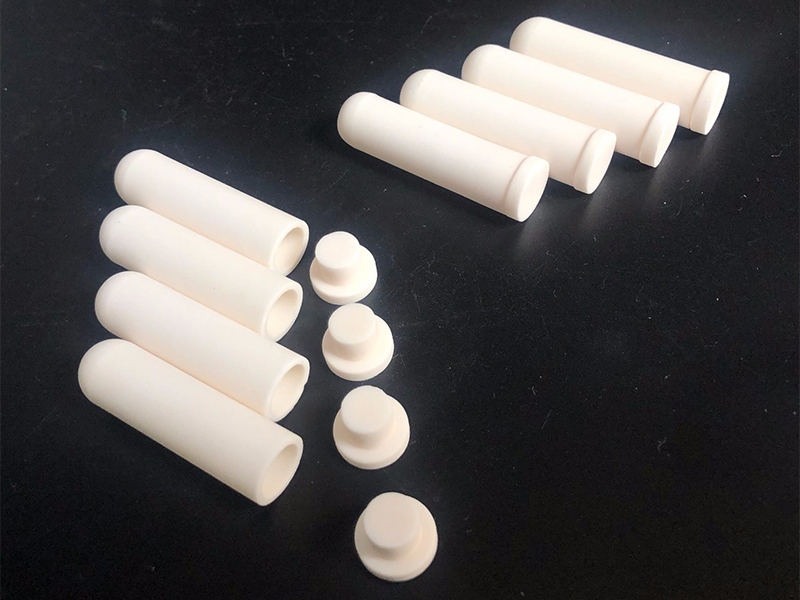

- Alumina Ceramic Tube

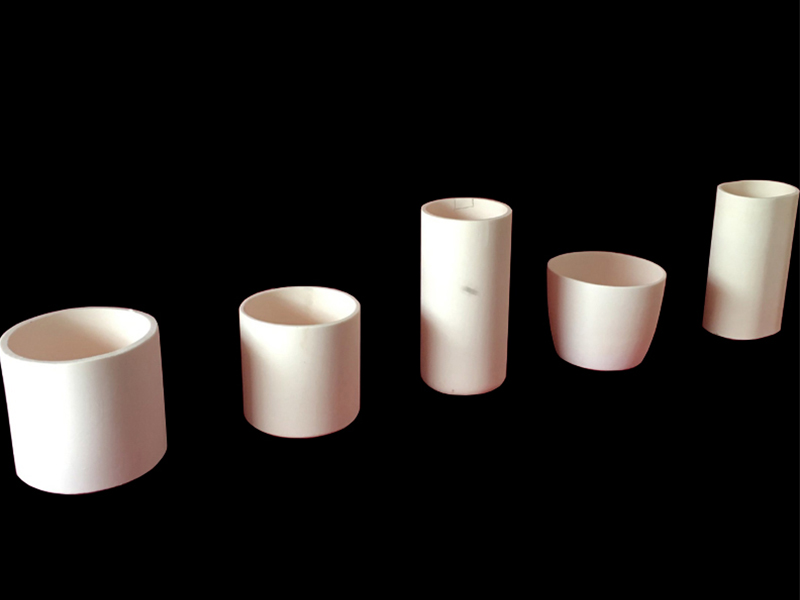

- Alumina Ceramic Crucible

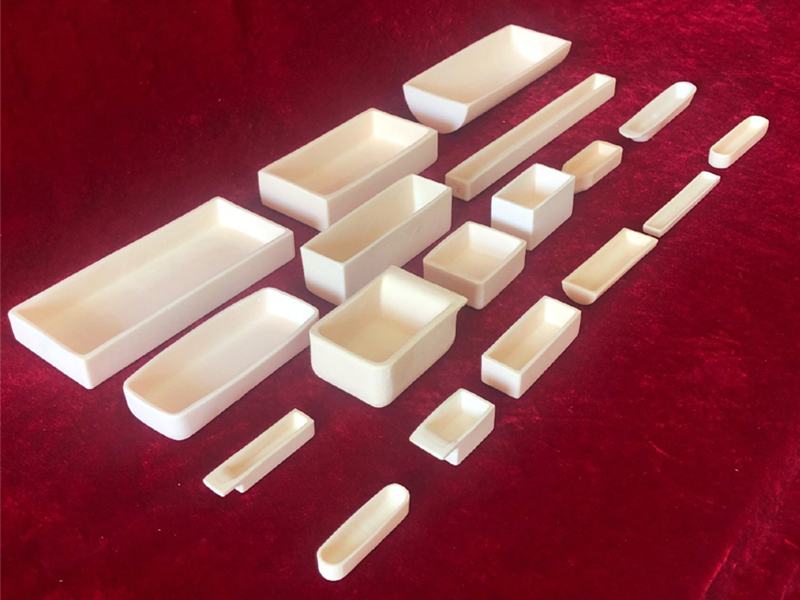

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search