09-02/2024

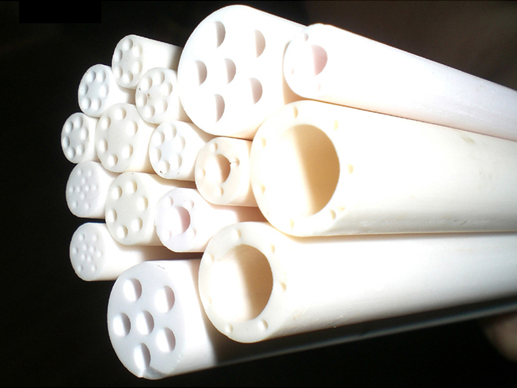

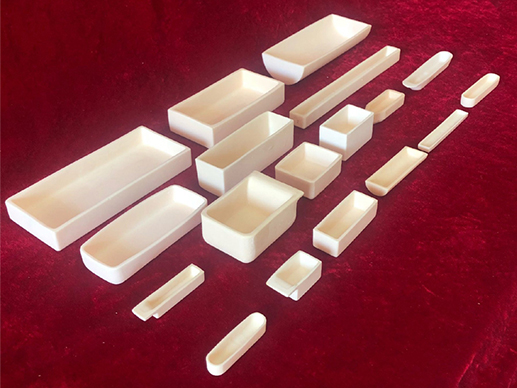

As industries worldwide continue to push the boundaries of high-temperature applications, the demand for materials that can withstand extreme conditions while maintaining precision and durability is ever-increasing. Among the various solutions available, alumina ceramic thermocouple tubes have emerged as a critical component in ensuring accurate temperature measurements in environments where conventional materials would fail.