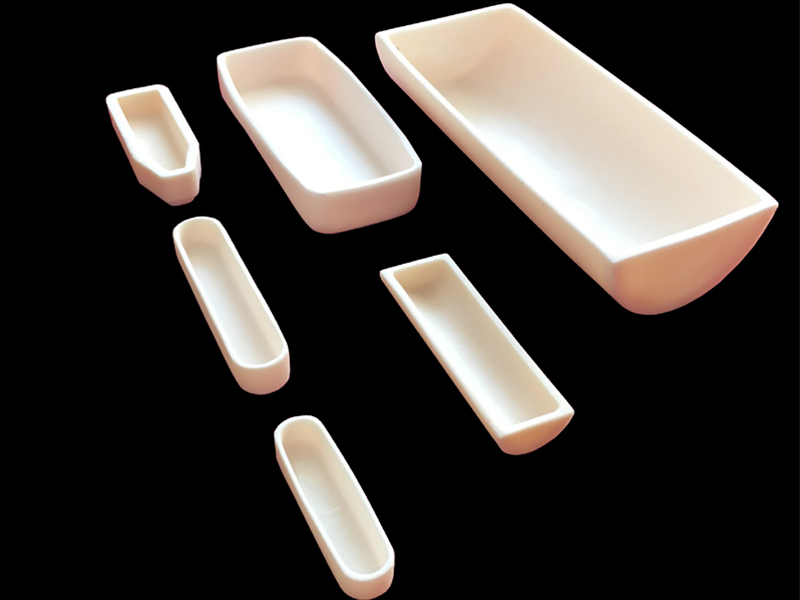

1. High Temperature Resistance: Alumina trays are capable of withstanding extreme temperatures, often exceeding 1700°C. This makes them ideal for use in high-temperature environments such as furnaces and kilns.

2. Chemical Stability: Alumina trays is highly resistant to chemical corrosion and does not react with most acids, alkalis, or molten metals. This ensures that the trays maintain their integrity in harsh chemical environments.

3. Mechanical Strength: With excellent mechanical properties, including high hardness and wear resistance, alumina trays are durable and can withstand heavy loads without deforming.

4. Electrical Insulation: Alumina trays is an excellent electrical insulator, which makes these trays suitable for applications where electrical conductivity must be minimized.

5. Thermal Shock Resistance: Alumina trays can endure rapid temperature changes without cracking or breaking, which is crucial in processes involving quick heating and cooling cycles.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

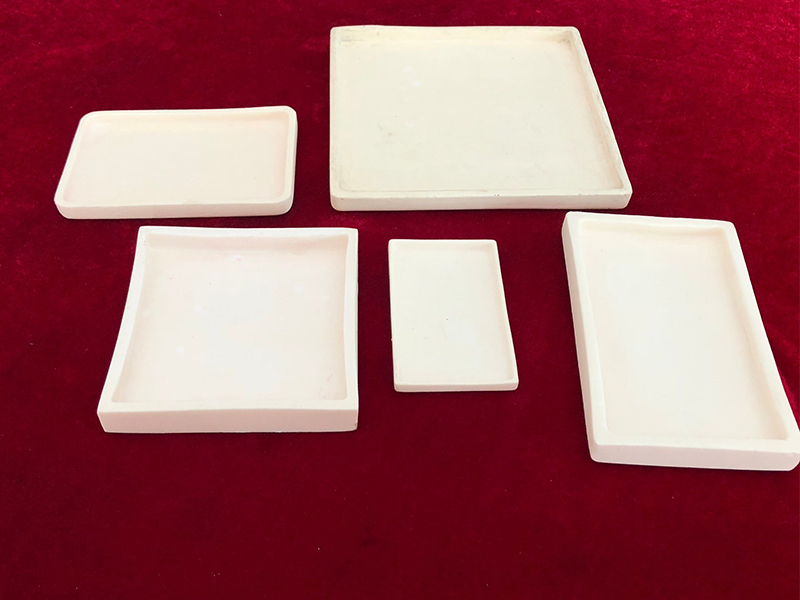

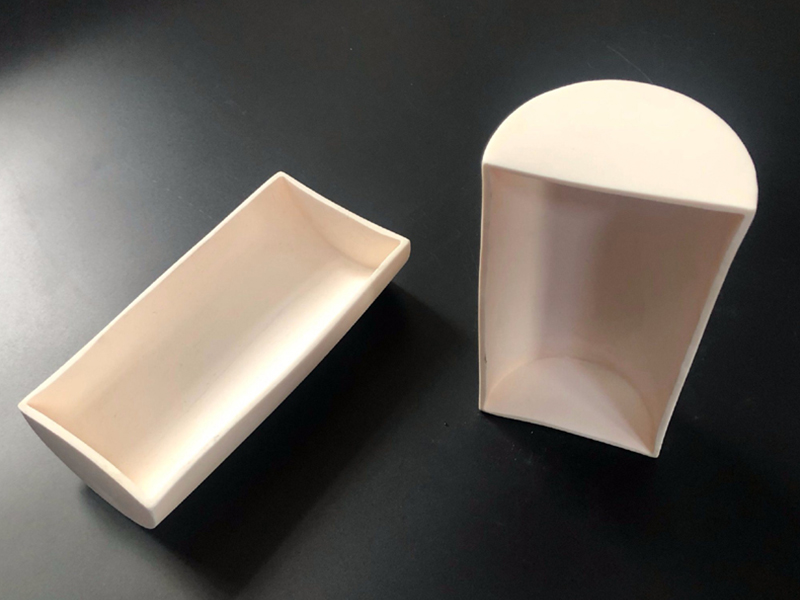

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search