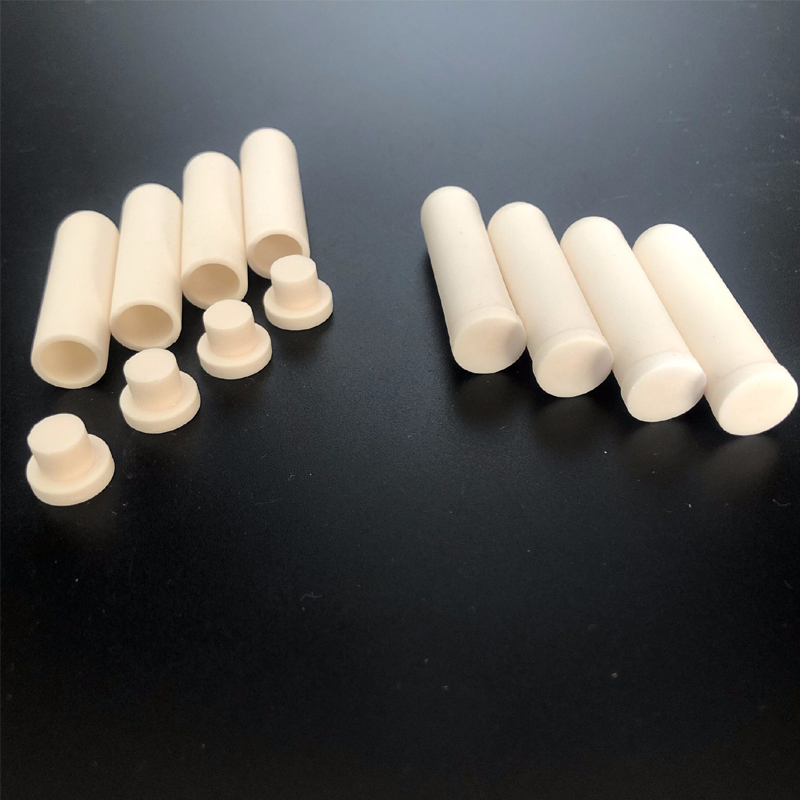

99.3% alumina crucible with lid: game changer for high-temperature applications

In the field of advanced materials engineering, alumina ceramics have long been the main material for high-performance applications. 99.3% alumina crucible with lid, this product has the potential to completely change the way industrial processes handle high temperatures. This high-purity alumina crucible has unparalleled advantages in environments where heat resistance, chemical inertness, and structural integrity are crucial.

What is a 99.3% alumina crucible?

A crucible is an essential laboratory tool designed to hold materials during high-temperature processes such as melting, heating, or chemical reactions. Aluminum oxide (Al2O3) is renowned for its excellent thermal and mechanical properties and is the preferred material for crucibles in industries such as metallurgy, chemical processing, and materials research.

The matching lid of the crucible further improves its practicality. By using crucibles during the manufacturing process, the lid provides an additional protective layer to prevent contamination, oxidation, and material loss. This characteristic is particularly important in controlled experiments and industrial processes, where maintaining purity and consistency is crucial.

Key Features of the 99.3% Alumina Crucible with Lid

1. High-Temperature Resistance: The 99.3% alumina composition ensures that the crucible can withstand extreme temperatures up to 1700°C (3092°F), making it ideal for a wide range of high-temperature applications in both laboratory and industrial settings.

2. Chemical Inertness: Alumina's chemical inertness allows the crucible to resist reactions with most acids, alkalis, and gases, ensuring that materials remain pure and uncontaminated during thermal processes. This feature is especially beneficial in industries that work with highly reactive substances.

3. Mechanical Strength: Despite the high temperatures involved, the alumina crucible maintains excellent mechanical stability. It is resistant to thermal shock, ensuring that it can endure rapid heating and cooling cycles without fracturing, making it highly durable and cost-effective over time.

4. Thermal Conductivity: The high thermal conductivity of alumina allows for efficient heat distribution within the crucible, ensuring uniform temperatures throughout the material. This property is essential in applications such as metal casting or sintering, where precise temperature control is critical.

5. Lid for Enhanced Performance: The inclusion of a lid adds significant value to the crucible. It helps in minimizing heat loss, preventing contamination, and improving thermal efficiency. The lid also ensures that volatile components within the crucible remain contained, improving the accuracy of experiments and industrial processes.

Looking Forward: The Future of Alumina Crucibles

As technology advances and industries demand more efficient and reliable high-temperature materials, products like the 99.3% alumina crucible with lid will continue to play a pivotal role. Whether in the development of new materials, the refinement of industrial processes, or the advancement of scientific research, high-purity alumina crucibles are essential tools for progress.

The introduction of this 99.3% alumina crucible with lid represents a significant leap forward in material technology. It offers not only superior thermal and mechanical performance but also the versatility and durability required by modern industries. With this innovative product, industries can look forward to achieving higher levels of precision, safety, and efficiency in their high-temperature processes.