1. Alumina Ceramic Sheet high temperature resistance: They can withstand temperatures up to 1600℃ in long use(Al2O3≥99%).

2. Alumina Ceramic Sheet high electrical insulation: Alumina ceramic substrates have a dielectric constant of 10 and can be used as an insulator for high voltage applications.

3. Alumina Ceramic Sheet low thermal expansion: They have a low coefficient of thermal expansion, making it suitable for applications that require a consistent temperature.

4. Alumina Ceramic Sheet chemical resistance: Highly resistant to corrosion, acids, alkalis, and solvents.

5. Alumina Ceramic Sheet high mechanical strength: Highly resistant to mechanical shock and vibration, making it suitable for use in dynamic environments.

6. Alumina Ceramic Sheet low cost: Relatively low cost compared to other materials with similar properties.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

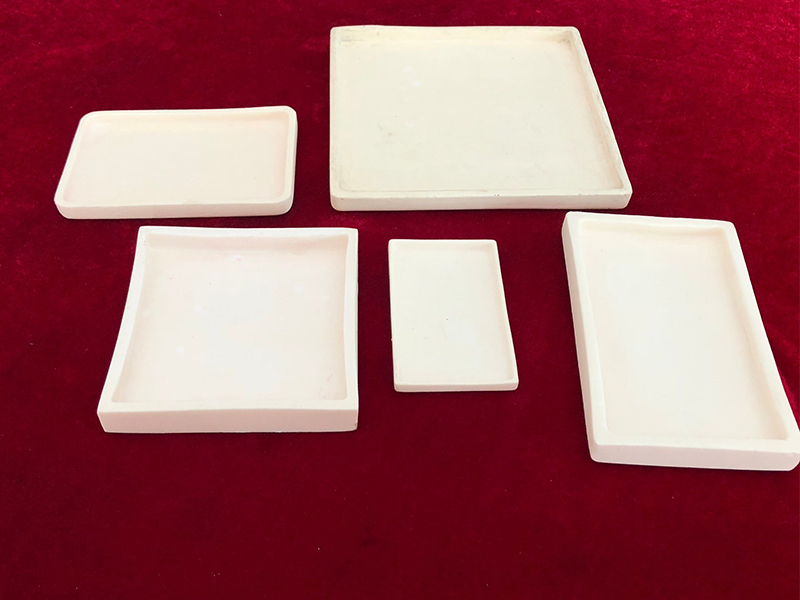

- Alumina Rectangular Trays

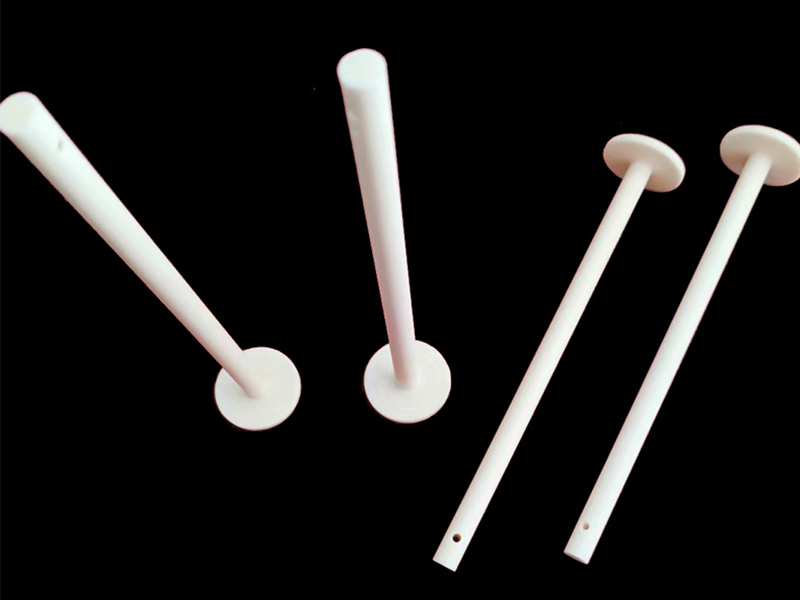

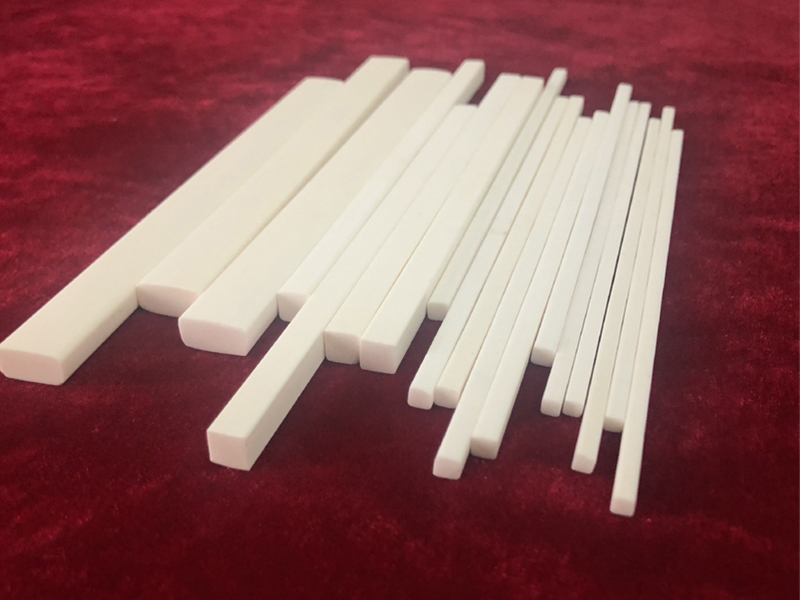

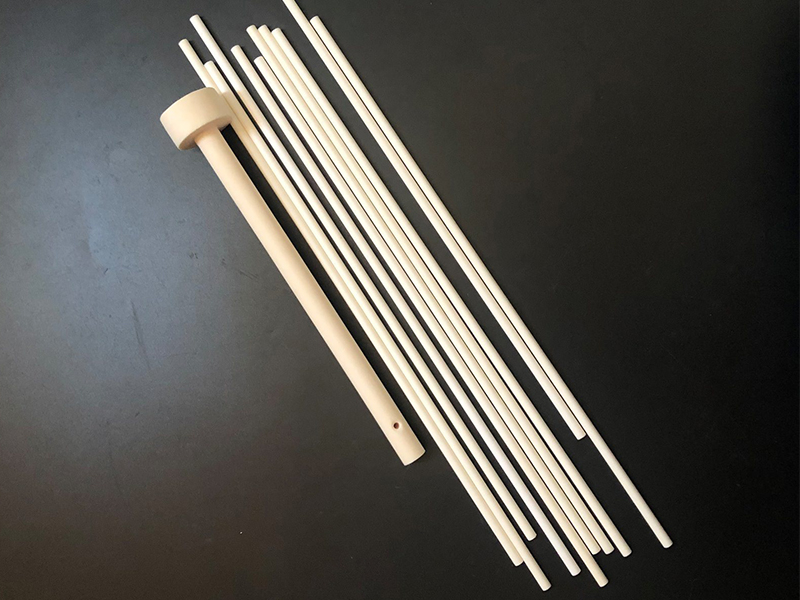

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

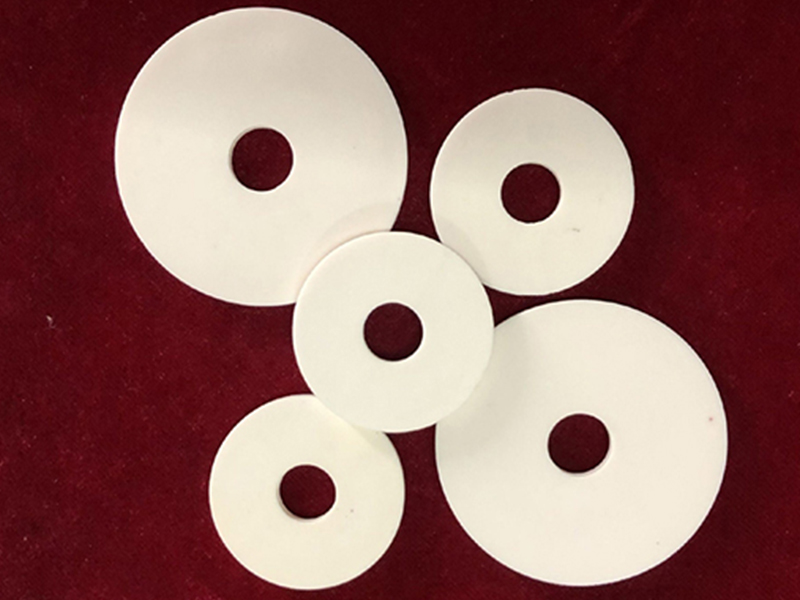

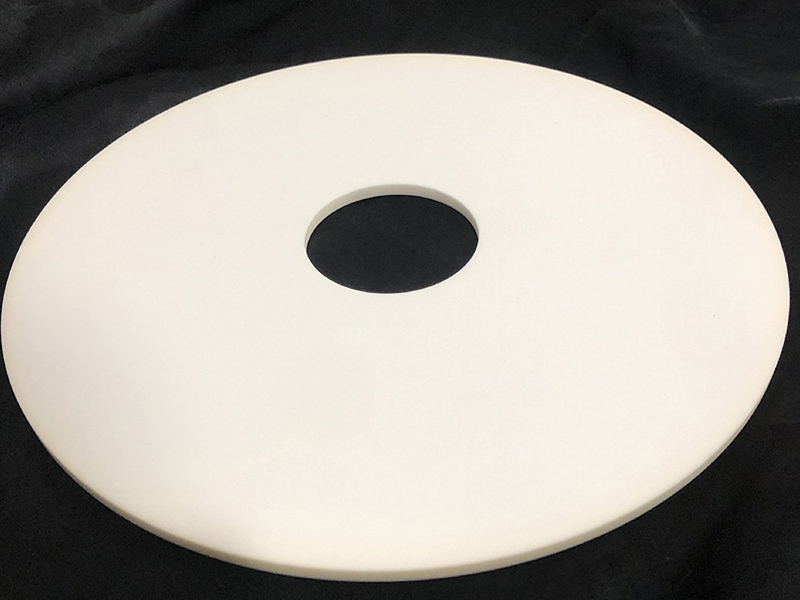

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search