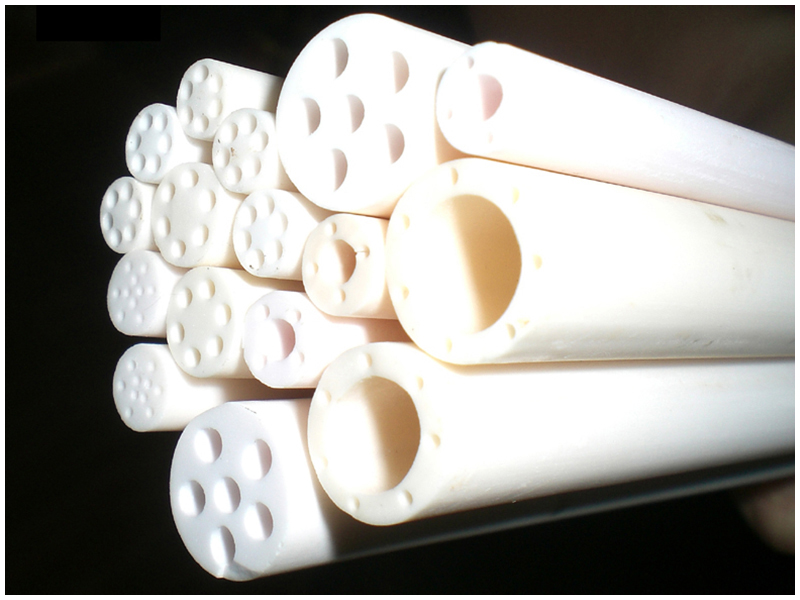

1.Alumina Ceramic Furnace Tubes are products made from the chemical compound with the same name ,alumina ceramic. Alumina ceramic, also known as aluminum oxide, is a combination of aluminum and oxygen.

2.Alumina Ceramic Furnace Tubes is extremely hard and durable, resistant to compressive strength, resistant to weathering, resistant to chemicals, electrically insulating, highly dense and stiff and incredibly thermally conductive.

3.Alumina Ceramic Furnace Tubes is up to twenty times more thermally conductive than the majority of other oxides.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

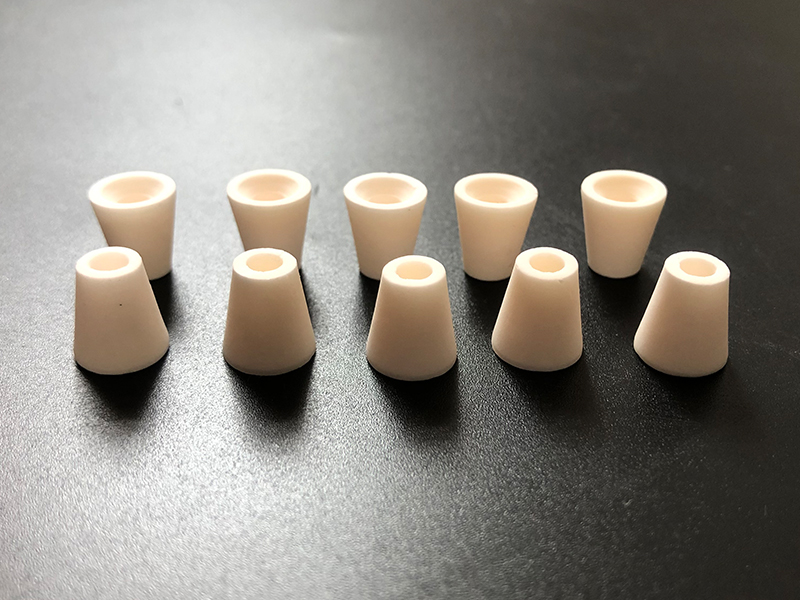

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

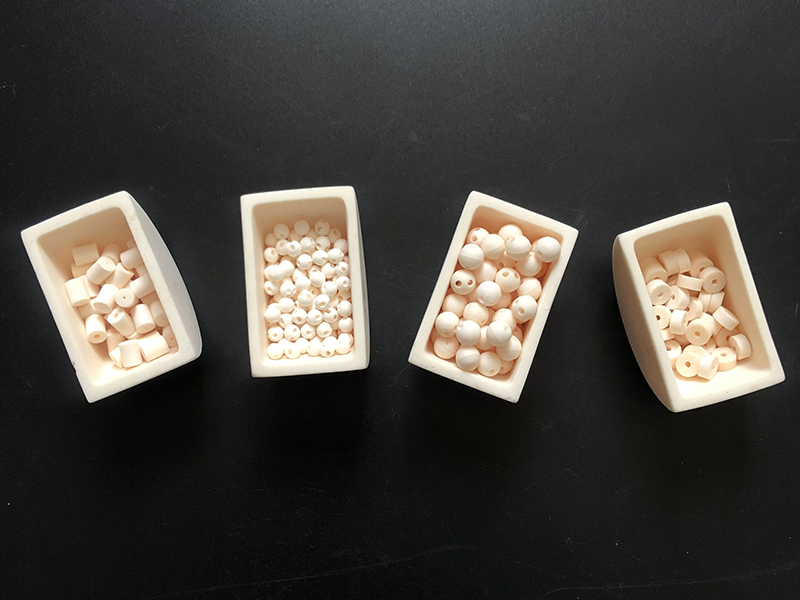

- Alumina Ceramic Beads

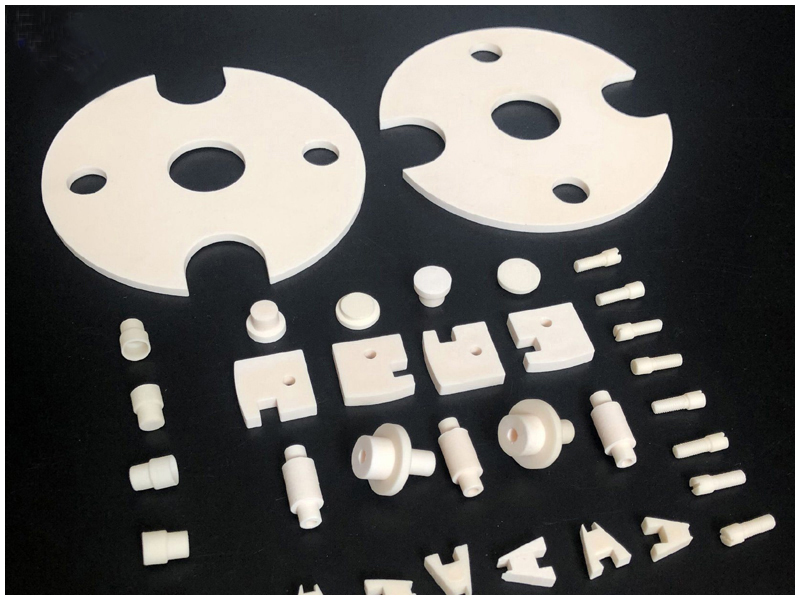

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search