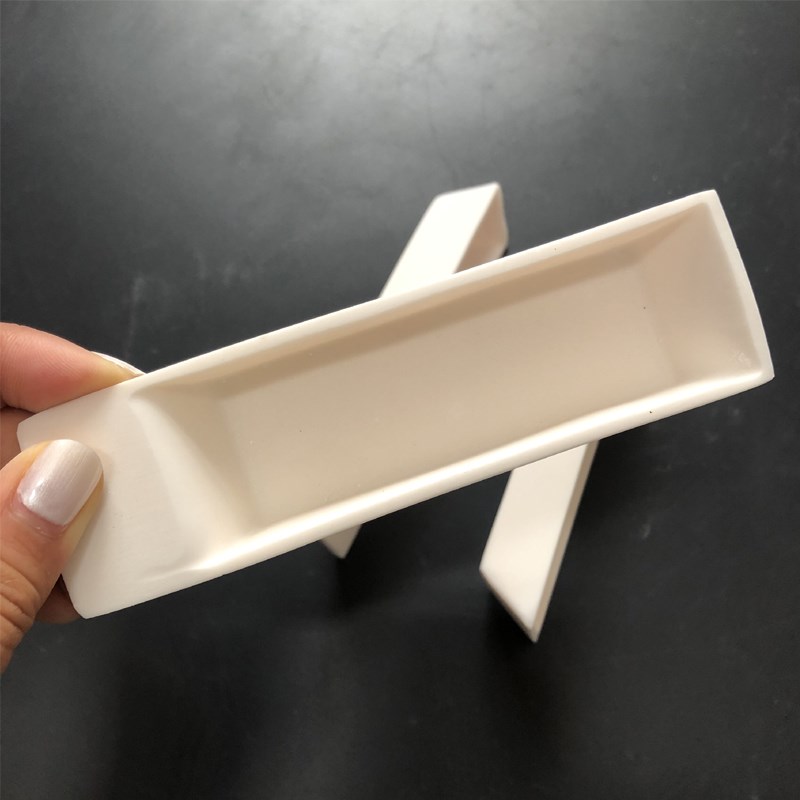

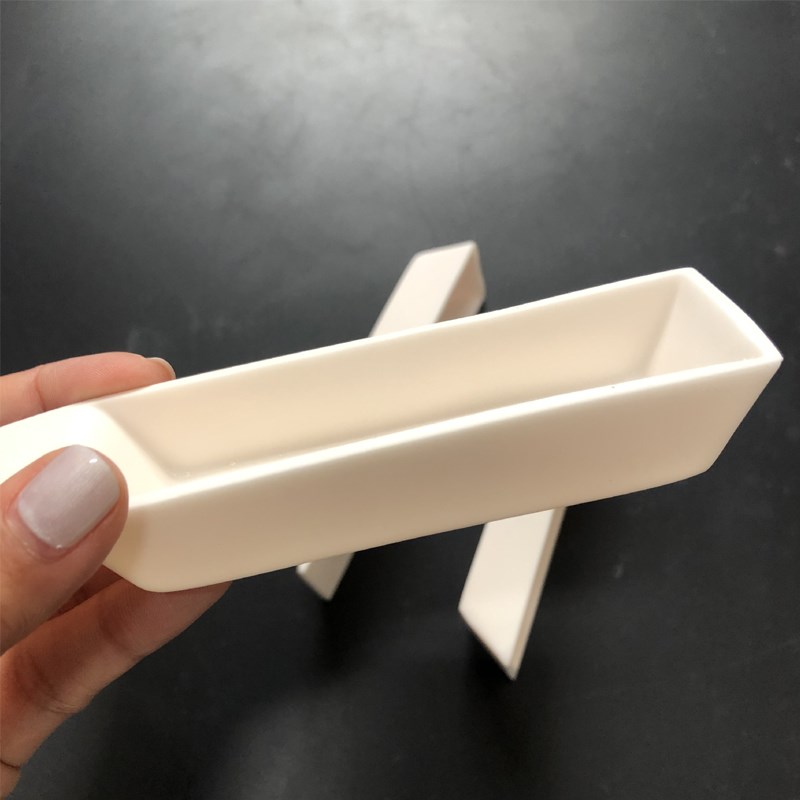

Alumina Ceramic Crucible With Stern

- yunxing

- china

- According to the quantity ordered

- 2000-5000/month(Looking for distributors)

1. Alumina ceramic crucible is a container made of aluminum oxide (Al2O3) ceramic material.

2. Alumina ceramic crucibles are commonly used for high-temperature applications in laboratory and industrial environments.

3. The design of alumina ceramic crucibles can withstand extreme temperatures and chemical reactions, and is suitable for melting, calcination, and heating various substances.

4. Alumina ceramic crucibles exhibit excellent thermal shock resistance, chemical inertness, and mechanical strength.

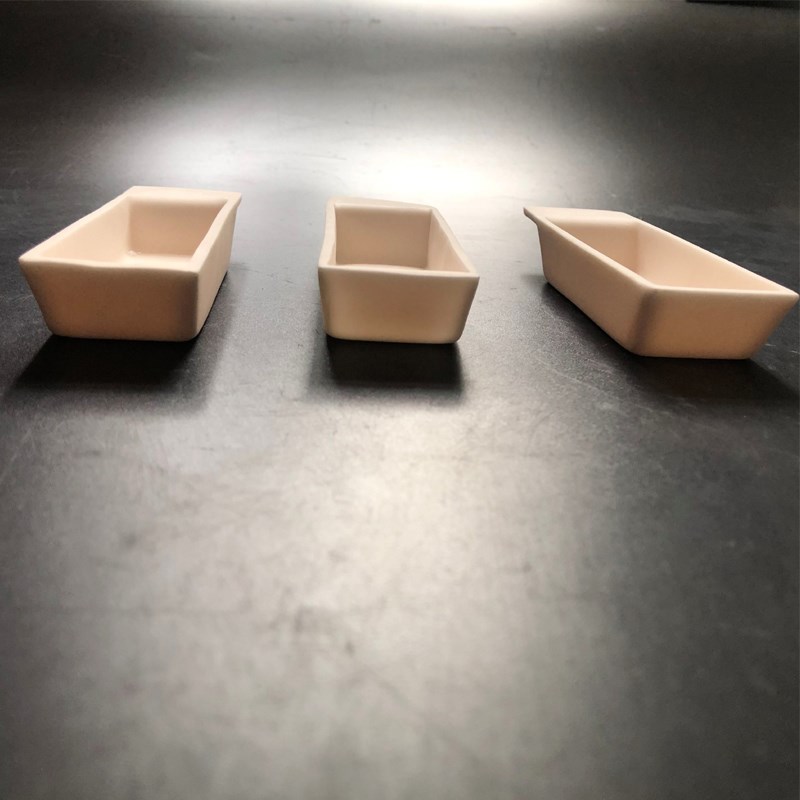

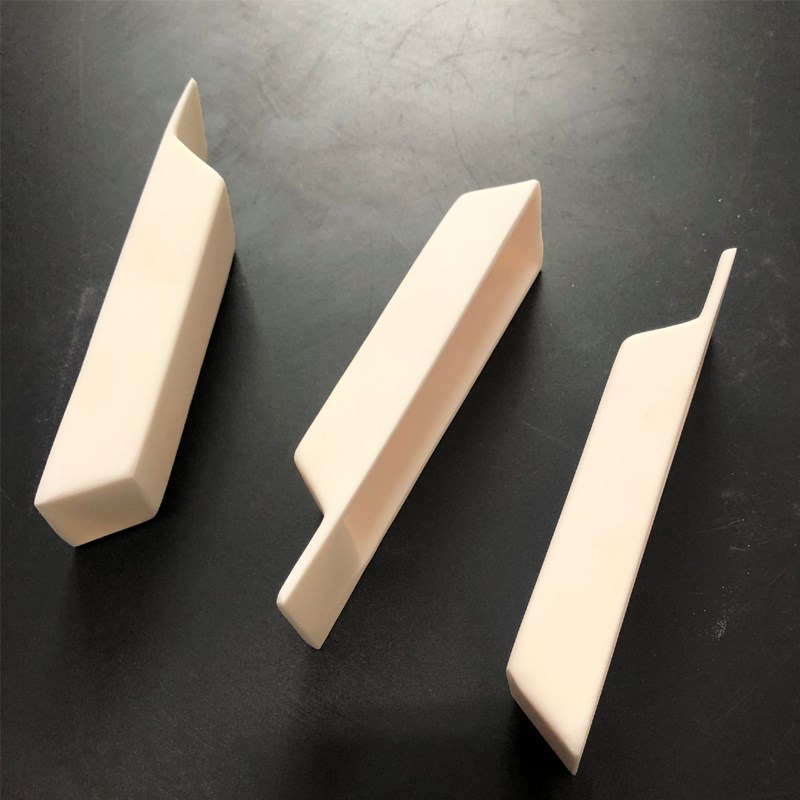

5. Alumina ceramic crucibles come in various shapes and sizes to meet different experimental or industrial requirements.

Alumina Ceramic Crucible With Stern

My factory looking for distributors.

Advantages of Alumina Ceramic Crucible With Stern

1. Alumina ceramic crucible is a container made of aluminum oxide (Al2O3) ceramic material.

2. Alumina ceramic crucibles are commonly used for high-temperature applications in laboratory and industrial environments.

3. The design of alumina ceramic crucibles can withstand extreme temperatures and chemical reactions, and is suitable for melting, calcination, and heating various substances.

4. Alumina ceramic crucibles exhibit excellent thermal shock resistance, chemical inertness, and mechanical strength.

5. Alumina ceramic crucibles come in various shapes and sizes to meet different experimental or industrial requirements.

Application of Alumina Ceramic Crucible With Stern

1. Metallurgy: Alumina ceramic crucibles have the advantage of high temperature resistance.

2. Chemical synthesis: Good corrosion resistance.

3. Material research: Alumina ceramic crucibles are used for sintering, calcining, and testing ceramics under controlled conditions.

4. Glass manufacturing: A crucible made of alumina ceramics is used in the glass production process to melt glass and conduct experiments to optimize glass composition and performance.

5. Analytical chemistry: They are used for sample preparation and analysis.

6. Semiconductor industry: Alumina ceramic crucibles are used for tasks such as crystal growth, annealing, and doping of semiconductor materials.

7. Precious metal refining: Due to their ability to withstand high temperatures and resist chemical reactions with molten metals.

8. Medication: Alumina ceramic crucibles are used for tasks such as drying, calcination, and catalyst preparation.

9. Powder metallurgy: They are used in the production of metal powders, including processes such as powder compaction and sintering.

10. Ceramic industry: Alumina ceramic crucibles provide a stable and controllable environment for sintering and firing processes.

All products through the German DIN standards: DIN43724 / DIN43725 / DIN40680

We only make high purity alumina ceramics

1. High-purity alumina content 99.3% -99.5%, other alumina ceramics 92% -99%.

2. The color of high purity alumina product is milky white, and other products are pink or white. The higher the purity, the more transparent the color.

3. Alumina is a refractory material, the higher the purity, the better the refractory effect.

4. After high-purity alumina ceramics are fired and cooled in a 1800-degree high-temperature kiln, the products are not easy to break when they encounter high temperatures. Other ceramics are fired at 1500 ℃ ~ 1800 ℃.

5. The volume density of high-purity alumina> 3.92 g / cm3 has a smooth surface and is not easily corroded by chemicals. The bulk density of other ceramics is> 3.70 g / cm3 ~> 3.85 g / cm3.

6. High purity alumina has good hardness and good wear resistance.

7. High purity alumina products have a longer service life.

Alumina crucible boats/Alumina ceramic trays | |||||||||

Item NO. | Length mm | Width mm | Height mm | Volume (mm) | Item NO. | Length mm | Width mm | Height mm | Volume (mm) |

175# | 30 | 20 | 15 | 5 | 076B | 50 | 10 | 10 | 2 |

113A | 62 | 32/22 | 16 | 18 | 161# | 65 | 65 | 65 | 180 |

154# | 80 | 50 | 7 | 20 | 171# | 80 | 55 | 15 | 47 |

076A# | 100 | 10 | 10 | 5 | 075# | 100 | 20 | 20 | 28 |

155# | 100 | 30 | 30 | 75 | 114# | 100 | 40 | 18 | 55 |

226# | 105 | 22 | 14 | 22 | 227# | 184 | 123 | 62 | 1120 |

138# | 300 | 36 | 18 | 132 | 113B# | 300 | 45/30 | 20 | 140 |

254# | 200 | 100 | 50 | 770 | 273# | 84 | 13/11 | 8 | 7 |

274# | 45 | 13/11 | 9 | 5 | 297# | 48 | 50/10 | 19 | |

303# | 100 | 50 | 30 | 100 | 341# | 150 | 35 | 25 | 86 |

338# | 100 | 20 | 20 | 28 | 344# | 100 | 35 | 20 | 46 |

355# | 60 | 30 | 20 | 22 | 359# | 130 | 130 | 60 | 793 |

360# | 145 | 145 | 12 | 128 | 372# | 60/10 | 30 | 20 | 20 |

373# | 60/10 | 50 | 30 | 63 | 382# | 175 | 90 | 26 | 254 |

396# | 100 | 100 | 17.5 | 100 | 414# | 250 | 100 | 70 | 1400 |

415# | 250 | 56 | 50 | 497 | 440# | 250 | 46/15 | 15 | 65 |

444# | 50 | 20 | 20 | 13 | 477# | 70 | 36 | 17 | 27 |

493# | 44 | 33 | 17 | 16 | 507# | 52 | 31 | 6 | 5 |

514# | 120 | 60 | 17 | 66 | 515# | 120 | 60 | 14 | 50 |

523# | 105/80 | 18/14 | 12 | 15 | 526# | 200 | 20 | 15 | 30 |

539# | 150 | 150 | 70 | 1275 | 429# | 69 | 22 | 11 | 12 |

575# | 200 | 100 | 40 | 600 | 591# | 313 | 45 | 30 | 335 |

606# | 76.2 | 12.7 | 12.7 | 7.5 | 614# | 120 | 83 | 53 | 385 |

630# | 160 | 160 | 50 | 1015 | 636# | 50 | 40 | 20 | 27 |

643# | 170 | 170 | 27 | 370 | 673# | 75 | 15 | 10 | 6 |

678# | 190 | 190 | 80 | 2430 | 689# | 101.6 | 38.1 | 21.08 | 58 |

695# | 200 | 200 | 50 | 1620 | 707# | 114.3 | 76.2 | 9.6 | 470 |

644# | 120 | 80 | 22 | 160 | 662# | 64 | 64 | 60 | 210 |

718# | 90 | 17 | 11.5 | 9 | 724# | 120 | 30 | 20 | 48 |

728# | 100 | 35 | 15 | 35 | 747# | 50 | 12 | 10 | 3 |

776# | 64 | 38 | 20 | 34 | 791# | 48 | 30 | 24 | 16 |

796# | 88.9 | 88.9 | 44.45 | 260 | 803# | 130 | 80 | 15 | 97 |

799# | 188 | 140 | 42 | 850 | 822# | 110 | 70 | 35 | 180 |

825# | 50 | 29 | 28 | 30 | 829# | 300 | 65 | 30 | 460 |

837# | 300 | 60 | 30 | 410 | 838# | 108 | 45 | 19 | 68 |

849# | 150 | 15 | 10 | 12 | 871# | 76 | 76 | 21 | 46 |

879# | 83 | 52 | 6.5 | 17 | 886# | 130 | 90 | 140 | 1300 |

889# | 100 | 100 | 27 | 180 | 890# | 120 | 60 | 25 | 135 |

906# | 206.38 | 152.4 | 133.35 | 3560 | 907# | 165.1 | 111.76 | 104.78 | 1560 |

910# | 50.8 | 50.8 | 6 | 8 | 916# | 150 | 65 | 19 | 140 |

918# | 250 | 200 | 100 | 4300 | 919# | 200 | 150 | 100 | 2500 |

920# | 170 | 170 | 100 | 2400 | 921# | 190 | 190 | 100 | 3000 |

959# | 300 | 220 | 70 | 3950 | 966# | 160 | 47 | 23.5 | 115 |

978# | 65 | 30 | 17 | 21 | 989# | 50 | 12 | 9 | 2.5 |

990# | 70 | 14 | 10 | 5 | 992# | 62 | 22 | 16 | 15 |

A20# | 83 | 12.7/11.7 | 4.5 | 5 | 805# | 13 | 13 | 8 | 0.6 |

A39# | 18 | 100 | 10 | 9 | A51# | 190 | 190 | 50 | 1460 |

A52# | 65 | 65 | 30 | 90 | A59# | 100 | 45 | 19 | 60 |

A92# | 95 | 48 | 74 | 215 | A93# | 107 | 60 | 69 | 330 |

A94# | 150 | 80 | 55 | 450 | A95# | 250 | 200 | 120 | 5240 |

B18# | 220 | 45 | 50 | 330 | B19# | 54 | 38 | 20 | 25 |

B23# | 40 | 30 | 6 | 5 | B34# | 15 | 8 | 100 | 5.5 |

B71# | 40 | 100 | 20 | B72# | 58 | 145 | 29 | ||

B90# | 125 | 125 | 85 | B96# | 105 | 22 | 14.5 | ||

B99# | 70 | 70 | 30 | C07# | 125 | 60 | 20 | ||

C09# | 137 | 27 | 21 | C34# | 250 | 250 | 50 | ||

C75# | 140 | 140 | 60 | C81# | 100 | 14 | 12 | ||

C84# | 150 | 150 | 95 | C88# | 75 | 50 | 11 | ||

D12# | 50 | 12 | 10 | D13# | 75 | 15 | 10 | ||

D14# | 90 | 17 | 11.5 | 801# | 55/45 | 13 | 9/2 | ||

D37# | 205 | 100 | 300 | D54# | 120 | 30 | 15 | ||

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 |

| >99.3 |

2 | SiO2 |

| — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption |

| 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 |

20—1000℃ coefficient of thermal expansion |

mm.10-6 /℃.m |

8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 |

20℃direct current insulation resistance |

Ohm/cm |

1014 |

13 |

High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our Factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

Q1.What is alumina crucible used for?

A: Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures. Used as a protector for high-temperature thermal couples. Used as a material for the chemical industry due to its high corrosion resistance.

Q2.What are industrial crucibles made of?

A: Crucibles and their covers are made of high temperature-resistant materials, usually porcelain, alumina or an inert metal.

Q3.What is the cost of a ceramic crucible?

A: Ceramic crucibles include 95 porcelain, 97 porcelain, and 99 porcelain. The unit price varies depending on the alumina content and size of the crucible. You can consult us at any time to explore and find the best products.

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.