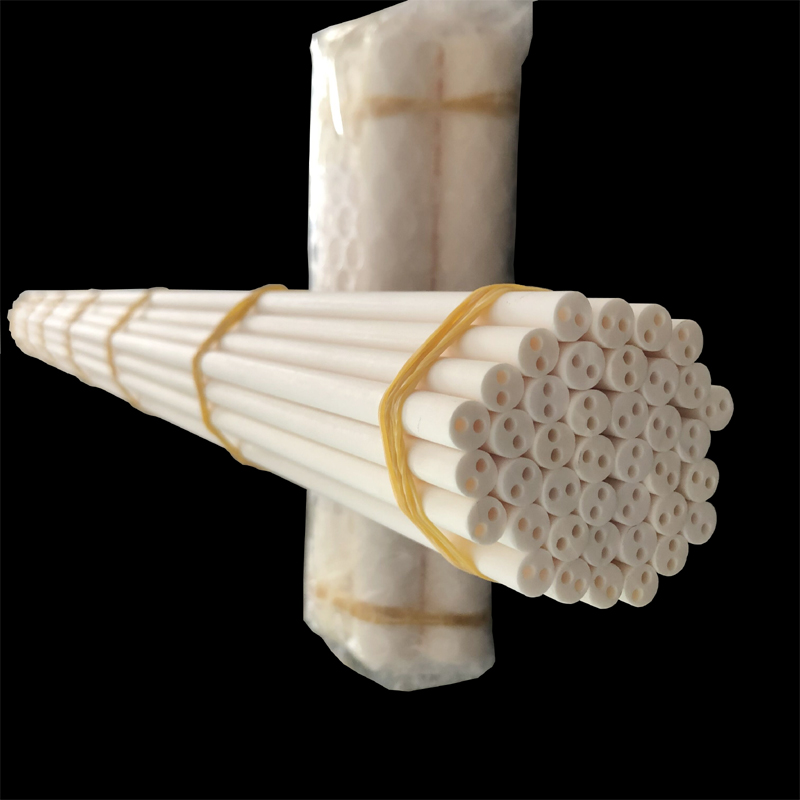

Industrial Alumina Ceramic 2 Hole Tube

- yunxing

- china

- It depends on the quantity of order

- 2000-5000/month(Looking for distributors)

Industrial alumina ceramic 2-hole tube, also known as insulated thermocouple protection tube. Its advantages:

Improve temperature accuracy

Our alumina ceramic 2-hole tube use advanced insulation materials to minimize the influence of external environmental factors and ensure more accurate temperature measurement.

Improving durability

With a sturdy insulation layer, our alumina ceramic 2-hole tube can withstand harsh conditions, including extreme temperatures, vibrations, and other environmental pressures. Extend the service life of pipelines, reduce maintenance and replacement costs.

Reduce energy costs

By effectively isolating pipelines, our solution helps maintain consistent temperatures, thereby reducing energy consumption in heating or cooling systems. Greatly saves operating costs.

Industrial Alumina Ceramic 2 Hole Tube

My factory looking for distributors.

Advanteges of Industrial alumina ceramic 2-hole tube

Industrial alumina ceramic 2-hole tube, also known as insulated thermocouple protection tube. Its advantages:

Improve temperature accuracy

Our alumina ceramic 2-hole tube use advanced insulation materials to minimize the influence of external environmental factors and ensure more accurate temperature measurement.

Improving durability

With a sturdy insulation layer, our alumina ceramic 2-hole tube can withstand harsh conditions, including extreme temperatures, vibrations, and other environmental pressures. Extend the service life of pipelines, reduce maintenance and replacement costs.

Reduce energy costs

By effectively isolating pipelines, our solution helps maintain consistent temperatures, thereby reducing energy consumption in heating or cooling systems. Greatly saves operating costs.

Enhanced security

In any industrial environment, safety is crucial. Our alumina ceramic 2-hole tube insulation technology not only improves temperature accuracy, but also reduces the risk of electric shock, ensuring a safer working environment for workers.

Corrosion resistance

The insulation layer of the alumina ceramic 2-hole tube serves as a protective barrier, minimizing direct contact between the pipeline and corrosive substances. Extend the service life of pipelines and minimize maintenance requirements.

In summary, our alumina ceramic 2-hole tubes provide unparalleled performance, durability, and safety advantages for various industrial applications. Experience differences in temperature accuracy, energy efficiency, and overall reliability using our advanced pipeline solutions.

Application of Industrial alumina ceramic 2-hole tube

1. Furnace work tubes

2. Kiln furniture, components & accessories

3. Thermocouple protection tubes

4.Heater Support Elements

5. High Temperature Electrical Insulators

6. Extreme temperature measurement components

7.Ceramic Laser components

8. High voltage electrical insulators

Insulation tube (extrusion) Specification Table

Number | 2 Bore tube SPEC: OD x ID | LENGTH MM | |

INCH | MM | ||

1 | 0.031x0.005 | 0.79x0.13 |

≤18500 |

2 | 0.039x0.008 | 1x0.2 | |

3 | 0.047x0.010 | 1.19x0.25 | |

4 | 0.062x0.016 | 1.57x0.41 | |

5 | 0.063x0.012 | 1.6x0.3 | |

6 | 0.079x0.020 | 2x0.5 | |

7 | 0.094x0.025 | 2.39x0.64 | |

8 | 0.118x0.028 | 3x0.7 | |

9 | 0.125x0.031 | 3.18x0.79 | |

10 | 0.125x0.040 | 3.18x1.02 | |

11 | 0.156x0.040 | 3.96x1.02 | |

12 | 0.158x0.039 | 4x1 | |

13 | 0.187x0.040 | 4.75x1.02 | |

14 | 0.187x0.062 | 4.75x1.57 | |

15 | 0.197x0.047 | 5x1.2 | |

16 | 0.236x0.059 | 6x1.5 | |

17 | 0.250x0.062 | 6.35x1.57 | |

18 | 0.250x0.078 | 6.35x1.98 | |

19 | 0.315x0.079 | 8x2 | |

20 | 0.375x0.062 | 9.53x1.58 | |

21 | 0.394x0.138 | 10x3.5 | |

22 | 0.473x0.158 | 12x4 | |

Insulation tube (extrusion) Specification Table

Number | 4 Bore tube SPEC: OD x ID | LENGTH MM | |

英寸 INCH | 毫米 MM | ||

1 | 0.031x0.005 | 0.79x0.13 |

≤18500 |

2 | 0.039x0.010 | 1x0.25 | |

3 | 0.047x0.010 | 1.19x0.25 | |

4 | 0.059x0.016 | 1.5x0.4 | |

5 | 0.063x0.016 | 1.59x0.41 | |

6 | 0.063x0.014 | 1.6x0.35 | |

7 | 0.094x0.020 | 2.39x0.51 | |

8 | 0.100x0.020 | 2.5x0.5 | |

9 | 0.118x0.020 | 3x0.5 | |

10 | 0.125x0.020 | 3.18x0.51 | |

11 | 0.156x0.031 | 3.96x0.79 | |

12 | 0.158x0.032 | 4x0.8 | |

13 | 0.187x0.031 | 4.75x0.79 | |

14 | 0.187x0.047 | 4.75x1.19 | |

15 | 0.197x0.047 | 5x1.2 | |

16 | 0.218x0.050 | 5.54x1.27 | |

17 | 0.236x0.059 | 6x1.5 | |

18 | 0.250x0.062 | 6.35x1.57 | |

19 | 0.313x0.062 | 7.95x1.57 | |

20 | 0.315x0.097 | 8x2 | |

21 | 0.394x0.079 | 10x2 | |

22 | 0.473x0.138 | 12x3.5 | |

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

Alumina ceramic performance index

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | - |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Cold compressive strength | MPa | 350 |

6 | 20ºC leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600ºC |

8 | Bonding in high temperature | not bonded in 1600ºC | |

9 | 20-1000ºC coefficient ofthermalexpansion | mm.10-6/ºC.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20ºCdirect current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000ºC MΩ | ≥0.08 |

1300ºC MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550ºC | |

15 | Maximum working temperature | ºC | 1800 |

Alumina ceramic introduction

Alumina ceramic primarily consists of aluminum oxide (Al2O3), which constitutes a minimum of 50% of its composition. This high concentration of alumina imparts remarkable mechanical strength, chemical inertness, and resistance to extreme temperatures. Various additives may also be incorporated to enhance specific characteristics, such as zirconia for improved toughness or silica for enhanced thermal shock resistance.

Alumina ceramic boasts an array of exceptional properties that render it indispensable across numerous industries. Its outstanding mechanical strength ensures structural integrity even under harsh operating conditions. Moreover, its high hardness and wear resistance make it ideal for applications subjected to abrasion and erosion. With excellent thermal conductivity and resistance to thermal shock, alumina ceramic serves capably in environments with fluctuating temperatures. Additionally, its superb electrical insulation properties find utility in electronic and electrical components.

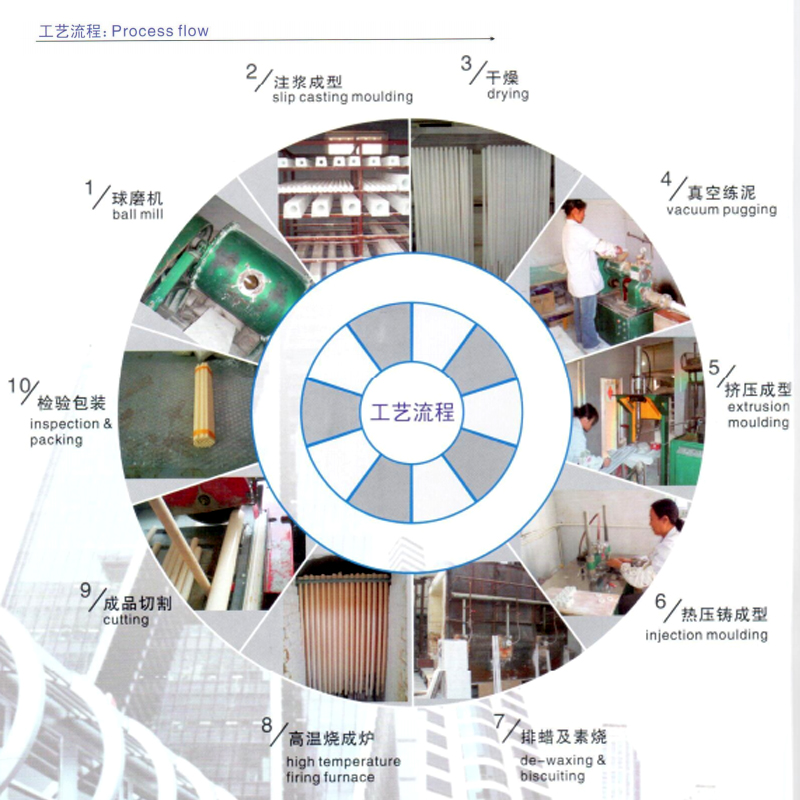

The production of alumina ceramic involves intricate processes to achieve desired characteristics and precision. Common techniques include powder compaction, followed by sintering at elevated temperatures to form dense, solid structures. Advanced manufacturing methods, such as hot pressing or hot isostatic pressing (HIP), may be employed to further enhance density and eliminate porosity, thereby augmenting mechanical properties.

Application of Alumina Ceramics

1.Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves.

2.Alumina ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

3.Alumina is the most commonly used abrasive grain in the woodwork and metalwork industry. This is because it does a better job than silicon carbide on several materials, including bare wood, painted surfaces, and metal.

4.Alumina ceramic materials are used in making spark plugs, which are useful in a wide variety of engines.

5.Transparent alumina ceramics are used in making high-pressure sodium lamps and infrared detection window material.

6.With an alumina content higher than 99%, alumina ceramics can be used as excellent electrical insulators. They also have a low dielectric loss, with a wide range of applications in electronics and electrical appliances.

7.Transparent alumina shows good permeability to visible light and infrared rays.

8.Other essential applications of alumina ceramics can be seen in seal rings, medical prostheses, laser tubes, thermocouple tubes, electronic substrates, ballistic armor, electrical insulators, grinding media, and wear components.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of alumina ceramics. For more information, please visit https://www.aluminapipe.com/.

Production process

FAQ

Q1. How to quickly obtain a quote?

Please clearly mark the height, outer diameter, inner diameter, wall thickness, purpose, and any special requirements, such as lips. To expedite the quotation, please provide the drawings.

Yes, alumina ceramic 2-hole tube can be used in high-pressure applications. Their excellent mechanical strength and resistance to thermal and chemical stresses make them suitable for demanding conditions.

Q3. Can alumina ceramic 2-hole tube withstand rapid temperature changes?

Q4. What is alumina ceramic used for?

Other essential applications of alumina ceramics can be seen in seal rings, medical prostheses, laser tubes, thermocouple tubes, electronic substrates, ballistic armor, electrical insulators, grinding media, and wear components.

Q5. Why is alumina expensive?

It is expensive, largely because of the amount of electricity required in the extraction process. Aluminium ore is called bauxite close bauxiteA rock that can be used to make aluminium.. The bauxite is purified to produce aluminium oxide, a white powder from which aluminium can be extracted.

Q6. How long does alumina last?

Material: Activated alumina, molecular sieve, life is different according to the temperature of the intake air.

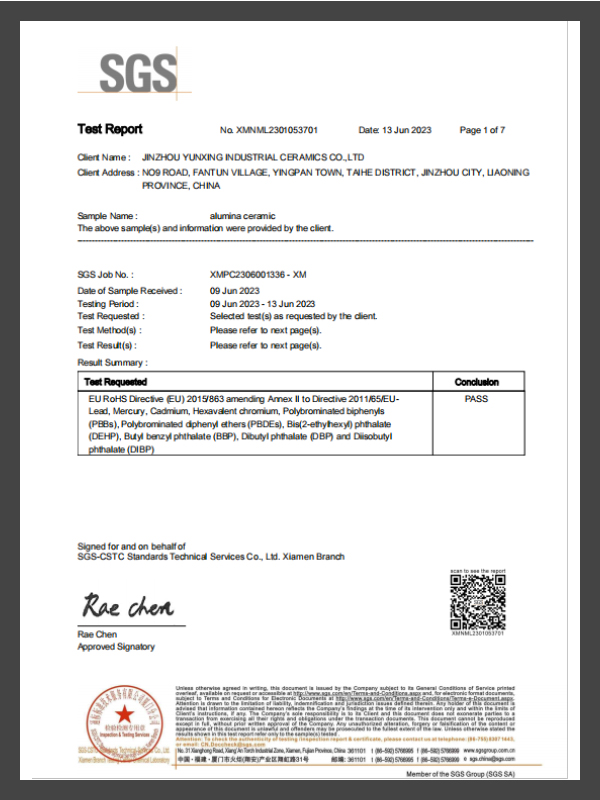

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.