12-14/2021

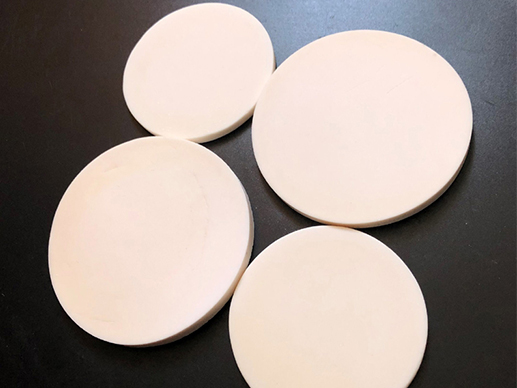

Alumina ceramics have the advantages of high impact toughness, good dielectric strength, low high frequency loss, high electrical and compressive strength, heat resistance, heat shock resistance, etc., and have the unmatched advantages of glass. It is suitable for high power on the market. Electron tube.