Number | SPEC: OD x ID | LENG TH MM | Number | SPEC: OD x ID | LENG TH MM |

| INCH | MM | INCH | MM |

| 1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 | ≤1800

|

| 2 | 0.236x0.157 | 6x4 | ≤1300 | 33 | 1.181x0.827 | 30x21 |

| 3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 |

| 4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 |

| 5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 |

| 6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 |

| 7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 |

| 8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 |

| 9 | 0.354x0.236 | 9x6 | ≤1600 | 40 | 1.654x1.339 | 42x34 |

| 10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 |

| 11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 |

| 12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 |

| 13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 |

| 14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 |

| 15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 |

| 16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 |

| 17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 |

| 18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 |

| 19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 |

| 20 | 0.591x0.394 | 15x10 | ≤1800 | 51 | 2.750x2.500 | 69.9x63.5 |

| 21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 |

| 22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 |

| 23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 |

| 24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 |

| 25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 | ≤1600 |

| 26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 |

| 27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 |

| 28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 |

| 29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 | ≤1500 |

| 30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 |

| 31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 |

Insulation tube (extrusion) Specification Table

| Number | 1 Bore tube SPEC: OD x ID | Length MM |

| INCH | MM |

1

| 0.031x0.011 | 0.8x0.3 |

≤18500 |

| 2 | 0.039x0.019 | 1x0.5

|

| 3 | 0.059x0.024 | 1.5x0.6

|

4

| 0.079x0.039

| 2x1

|

5

| 0.100x0.050 | 2.5x1.3 |

| 6 | 0.118x0.059 | 3x1.5 |

| 7 | 0.118x0.079 | 3x2 |

| 8 | 0.125x0.063 | 3.2x1.6 |

| 9 | 0.157x0.079 | 4x2 |

10

| 0.197x0.118 | 5x3 |

| 11 | 0.236x0.118 | 6x3 |

| 12 | 0.236x0.157 | 6x4 |

13

| 0.250x0.125 | 6.4x3.2 |

| 14 | 0.250x0.157 | 6.4x4 |

| 15 | 0.250x0.188 | 6.4x4.8 |

| 16 | 0.276x0.197 | 7x5 |

17

| 0.315x0.197 | 8x5 |

| 18 | 0.354x0.236 | 9x6 |

19

| 0.374x0.250 | 9.5x6.35 |

| 20 | 0.394x0.236 | 10x6 |

21

| 0.433x0.276 | 11x7 |

| 22 | 0.472x0.315 | 12x8

|

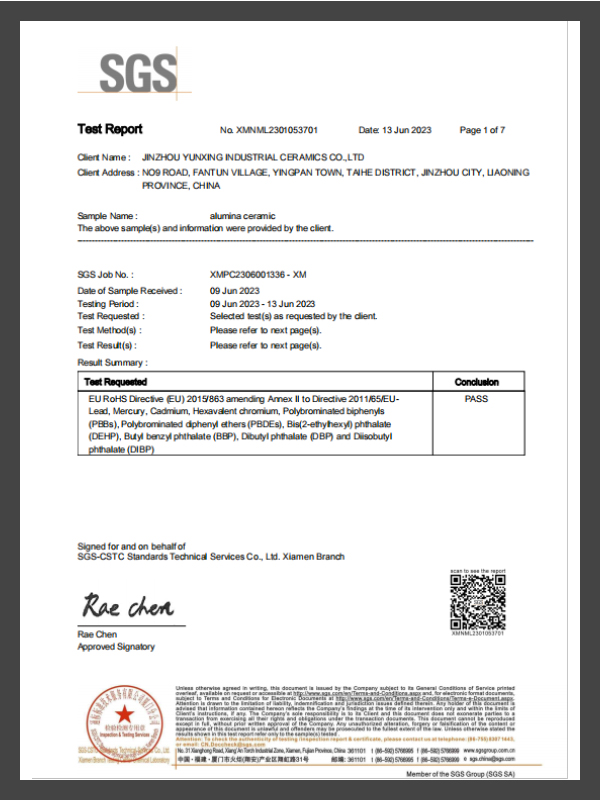

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature |

| not bonded in 1600℃ |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 |

14 | Thermal shock resistance |

| 4 times not cracked in 1550℃ |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

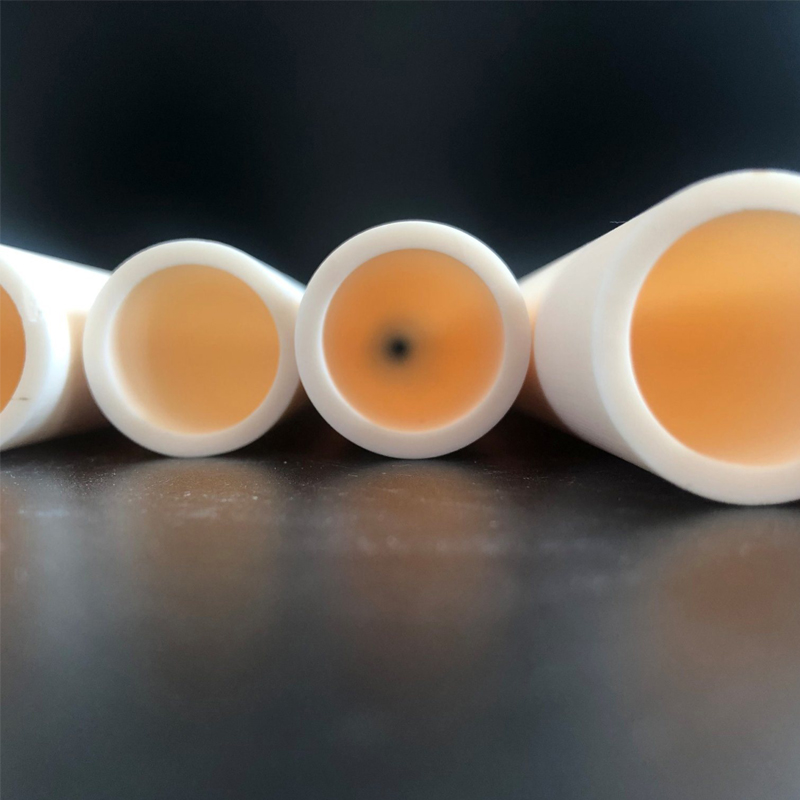

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Q1. Can alumina tubes be reused?

A1. Yes, alumina tubes can indeed be reused after they've been used, as long as they remain undamaged and free from

any contamination. It's essential to thoroughly clean and inspect them to confirm that they're still in good condition and suitable

for future use.

Q2. Is it safe to use alumina tubes in high-pressure applications?

A2. Indeed, alumina tubes are well-suited for high-pressure applications. Their exceptional mechanical strength, combined

with resistance to thermal and chemical stresses, renders them capable of withstanding rigorous conditions.

Q3. Can alumina tubes withstand rapid temperature changes?

A3. Certainly, alumina tubes demonstrate commendable thermal shock resistance, enabling them to endure rapid

temperature fluctuations without experiencing cracks or fractures.

Q4. Can alumina tubes be customized according to specific environments?

A4. Indeed, numerous suppliers provide the option to customize alumina tubes according to specific requirements. This

customization may involve modifications to dimensions, form, and the incorporation of additional features, ensuring alignment

with the precise needs of your application.

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.