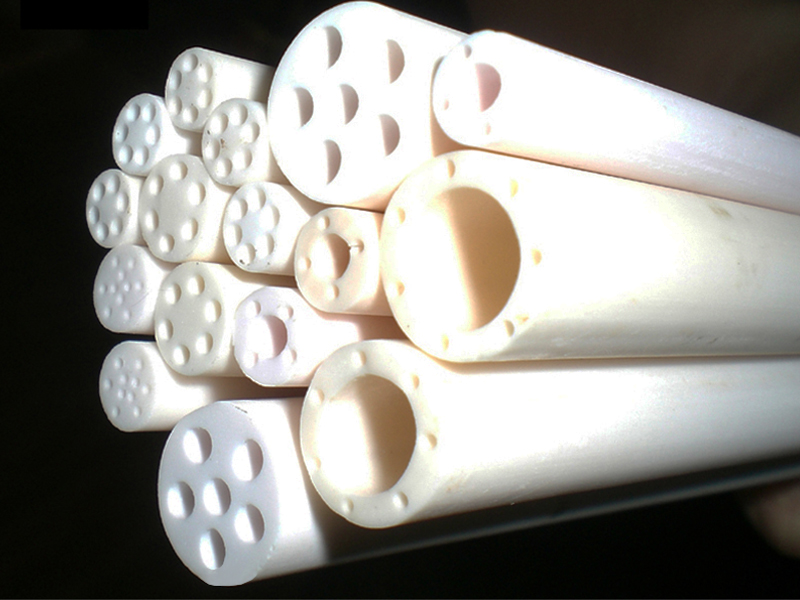

1. The composition of alumina tubes is mainly composed of alumina (Al2O3).

2. Alumina tubes exhibit significant resistance to high temperature, corrosion, wear, and chemical reactions.

The design of the alumina tube ensures effective heat transfer while providing a sturdy barrier against external components.

4. The smooth surface finish of the alumina tube minimizes the risk of contamination and accumulation.

5. Alumina tubes provide an economical and efficient solution for improving equipment life and performance in challenging industrial environments.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search