1. High Temperature Resistance: Alumina Ceramic Element Parts can withstand high temperatures, making them suitable for applications in environments with extreme heat.

2. Mechanical Strength: Alumina Ceramic Element Parts have excellent mechanical properties, including high hardness and stiffness, which make them durable and resistant to wear and abrasion.

3. Chemical Resistance: Alumina Ceramic Element Parts are highly resistant to many chemicals, acids, and alkalis, making them suitable for use in corrosive environments.

4. Electrical Insulation: Alumina Ceramic Element Parts have good electrical insulation properties, making them ideal for applications requiring electrical insulation and high dielectric strength.

5. Low Thermal Conductivity: Alumina Ceramic Element Parts have low thermal conductivity, which allows them to act as effective thermal insulators in various applications.

6. Biocompatibility: Alumina Ceramic Element Parts are biocompatible, meaning they are safe for use in medical implants and devices without causing adverse reactions in the body.

7. Dimensional Stability: Alumina Ceramic Element Parts exhibit excellent dimensional stability, maintaining their shape and size even under extreme conditions, such as high temperatures or mechanical stress.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

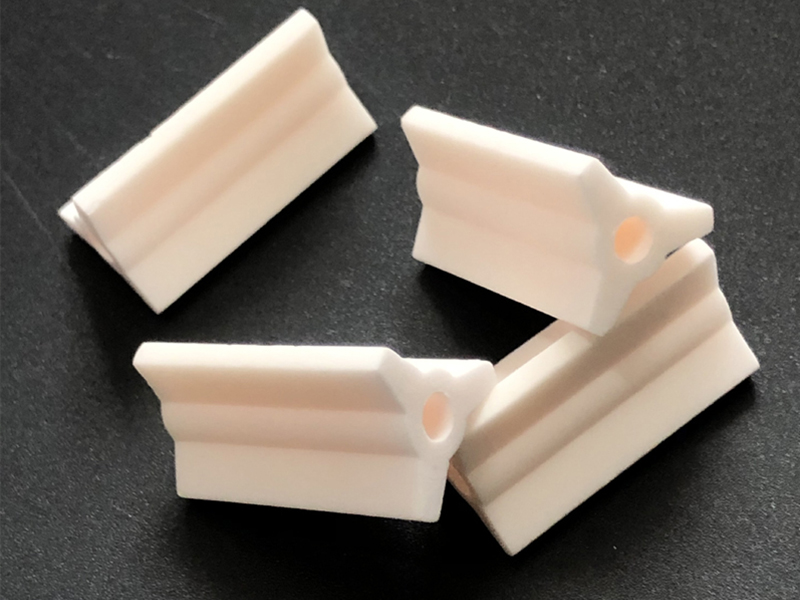

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search