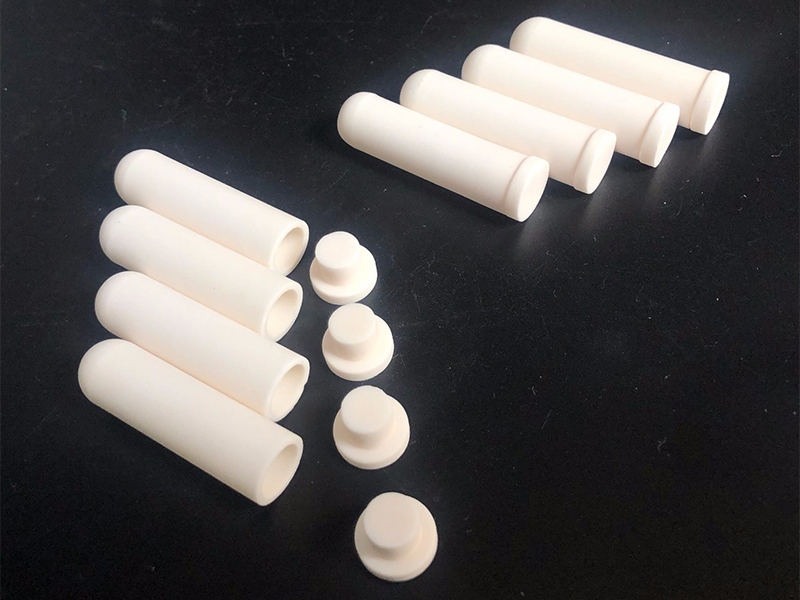

1. High temperature resistance:1600℃ in long use,1800℃ in short use. This makes it an ideal solution for various thermal processing applications.

2. Excellent thermal shock resistance: Alumina crucibles boat have excellent thermal shock resistance, which means they can withstand rapid changes in temperature without cracking or breaking.

3. Non-reactive: Alumina crucibles boat are non-reactive, which means they won't react with the substances being heated, melted or cast inside them, ensuring the purity of the final product.

4. Corrosion and Chemical Resistance: The ceramic material used in the alumina crucible boat exhibits excellent chemical resistance and resistance to corrosion. As a result, it can handle harsh chemicals and acids that might otherwise damage other materials.

5. Minimal Thermal Expansion: The alumina crucible boat has minimal thermal expansion, which means that it will maintain its shape and size at high temperatures, avoiding any potential risks of.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

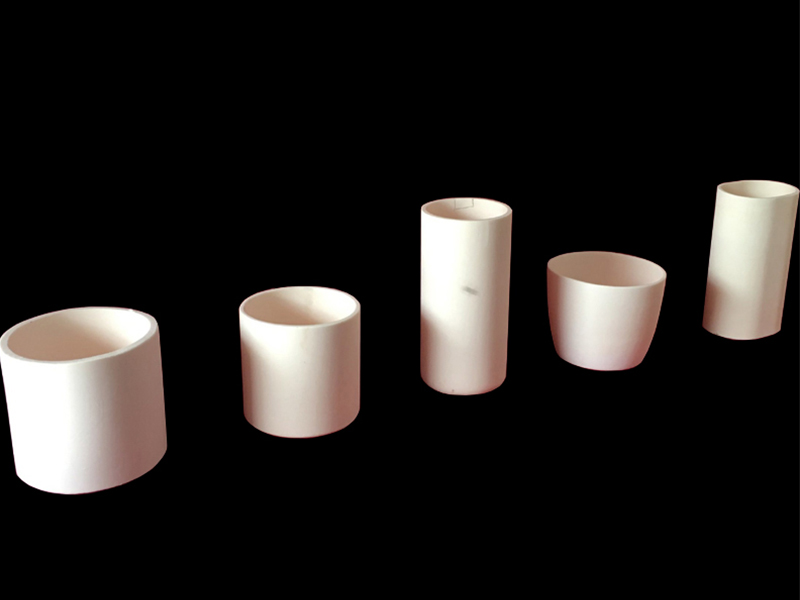

- Alumina Ceramic Crucible

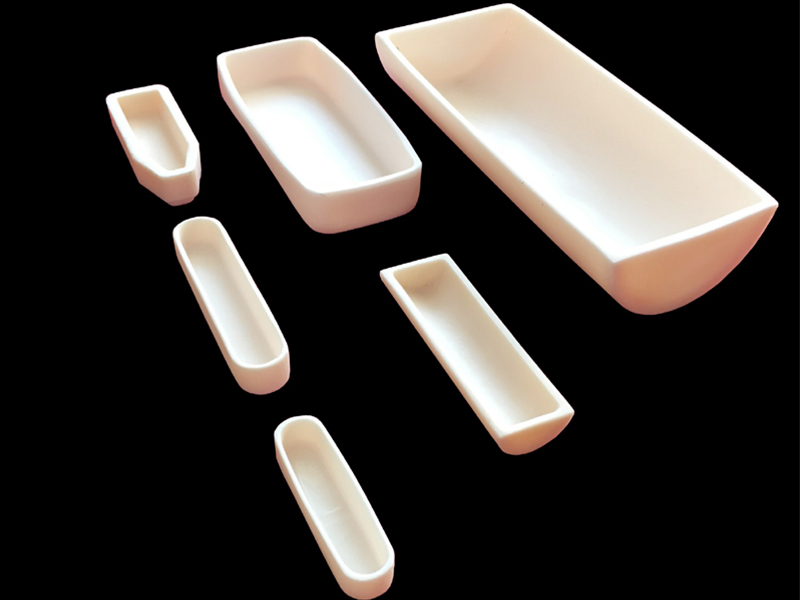

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search