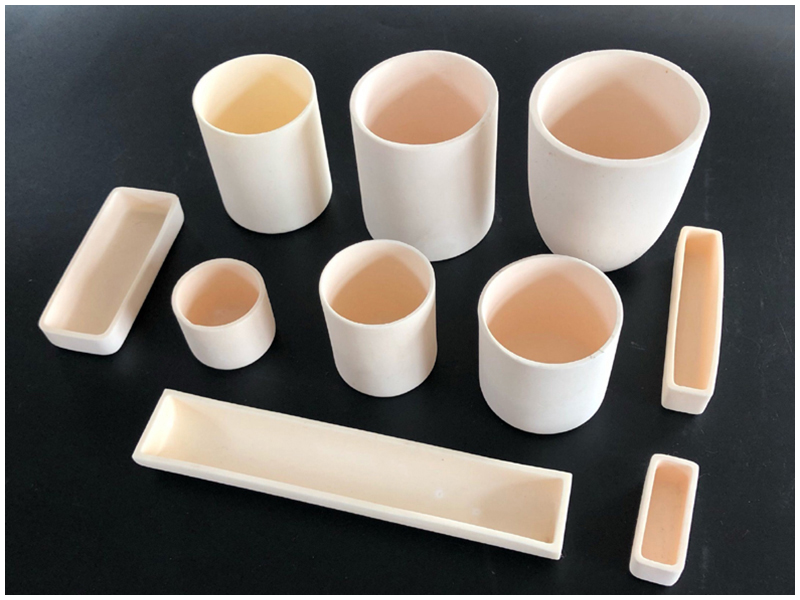

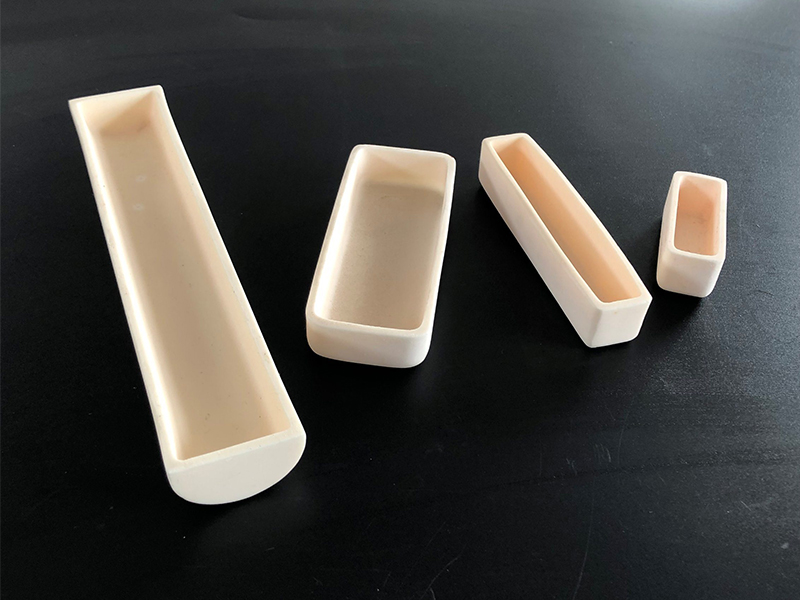

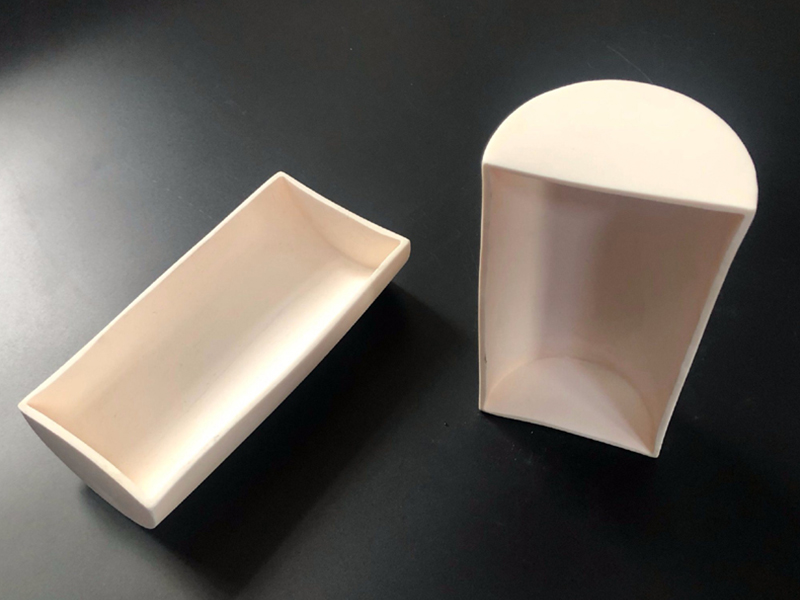

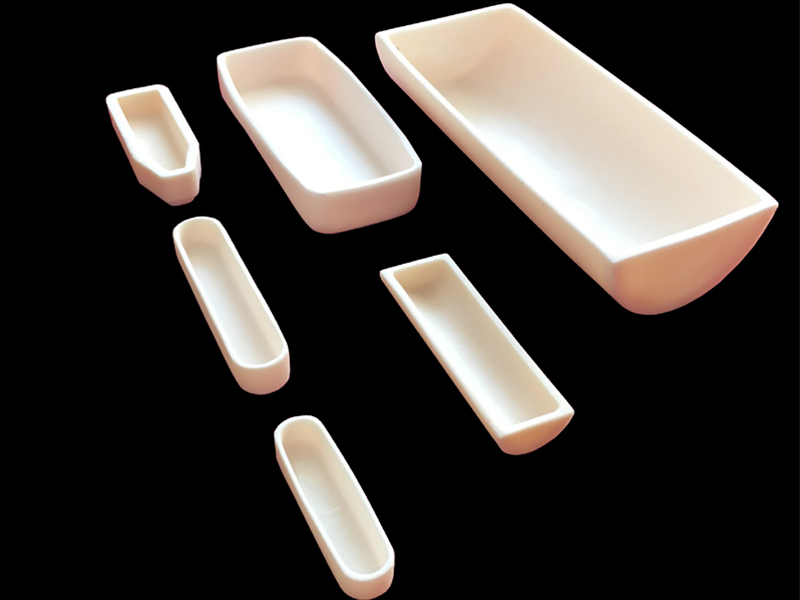

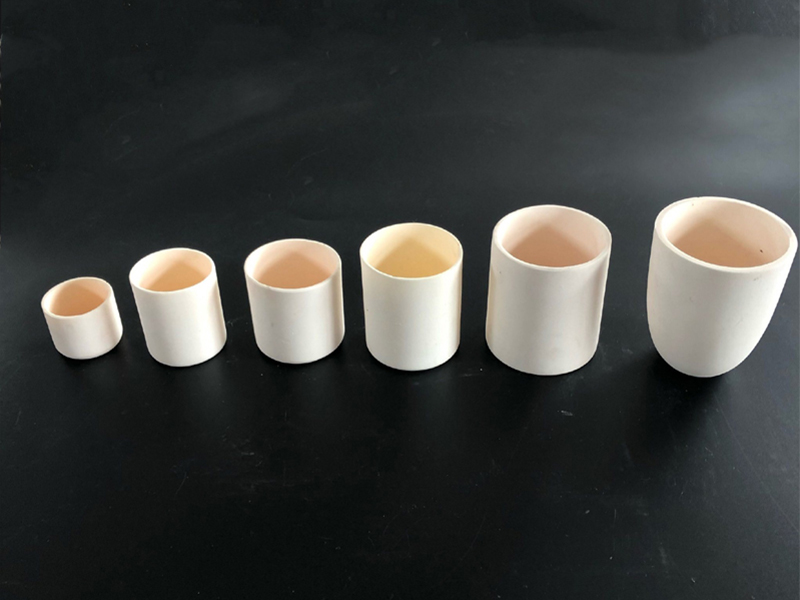

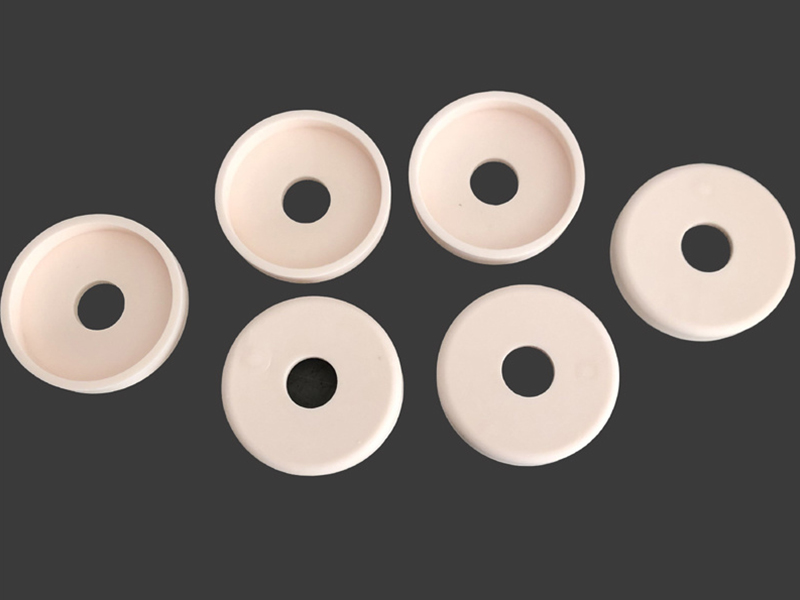

1. Alumina refractory ceramic crucibles crafted from high-purity alumina.

2. Alumina refractory ceramic crucibles offering exceptional thermal stability and chemical resistance.

3. Characterized by their robustness and durability, alumina refractory ceramic crucibles withstand extreme temperatures.

4. The chemical inertness of alumina refractory ceramic crucibles ensures minimal contamination, preserving the purity of the materials being processed.

5. Alumina refractory ceramic crucibles exhibit high mechanical strength.

6. Alumina refractory ceramic crucibles play a vital role in experimentation, offering a reliable vessel for conducting reactions at elevated temperatures.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search