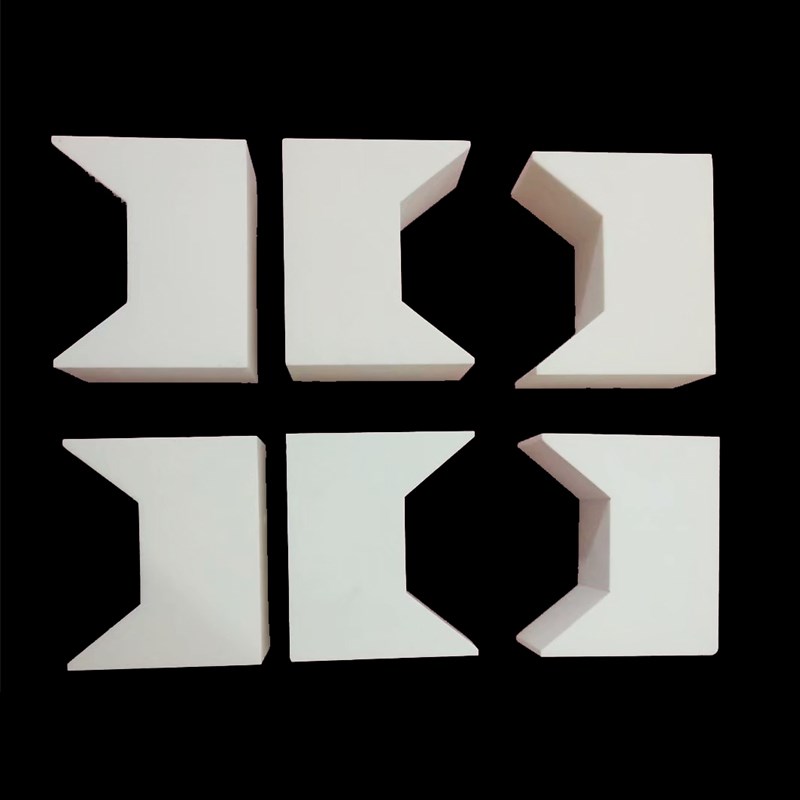

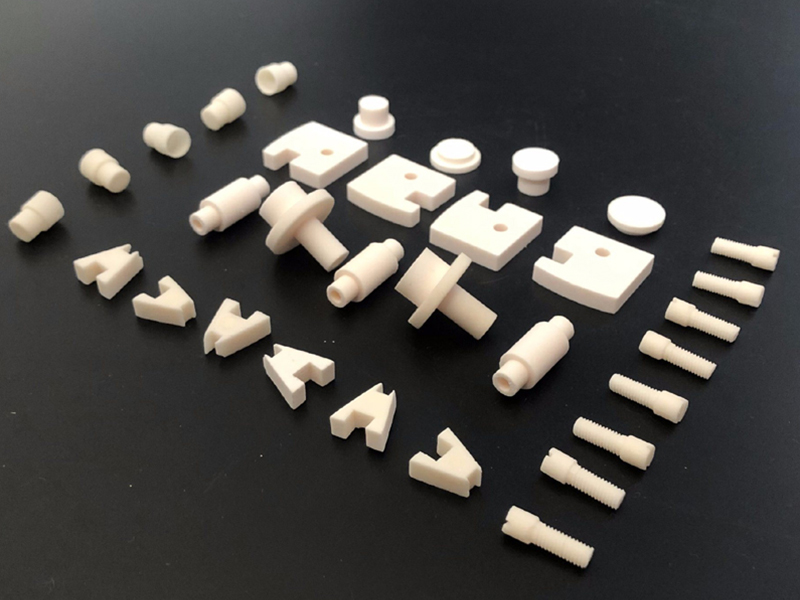

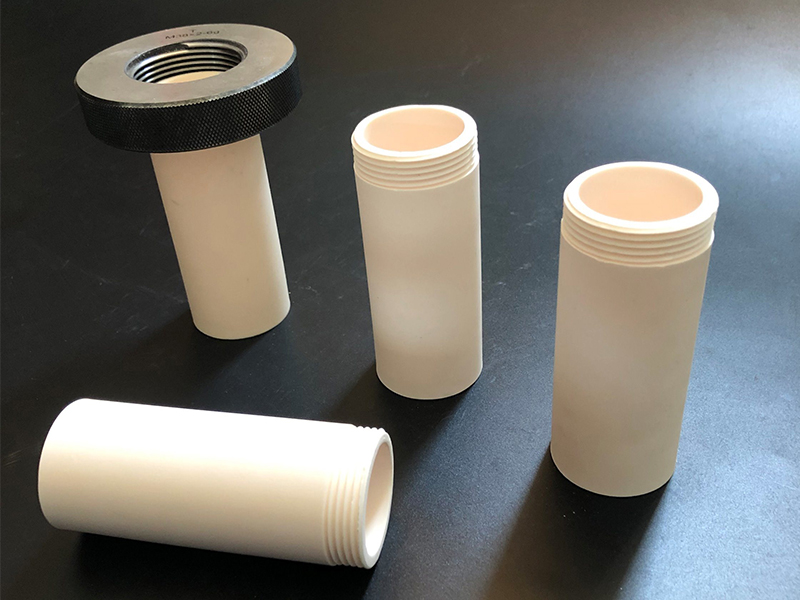

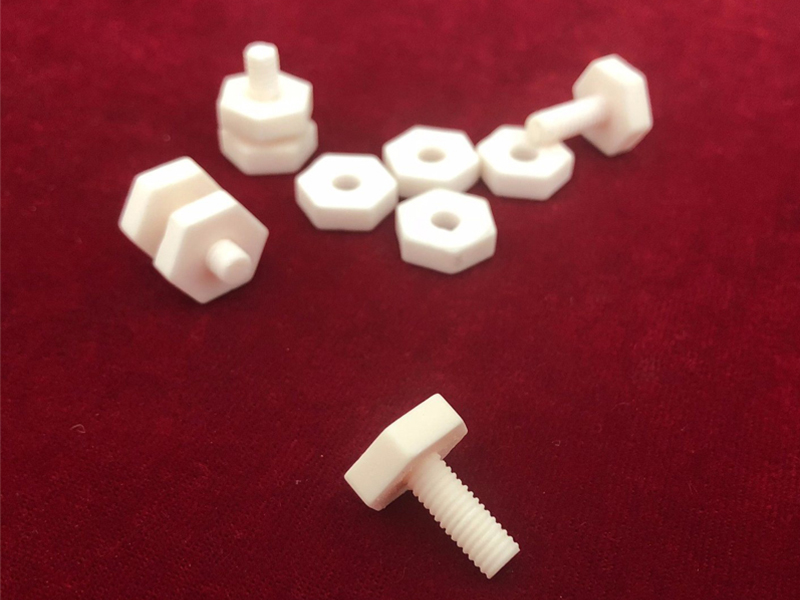

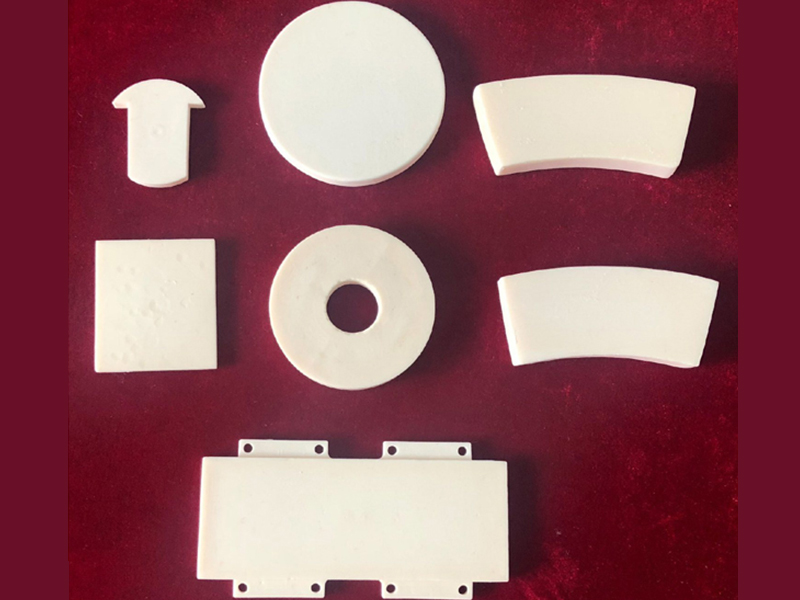

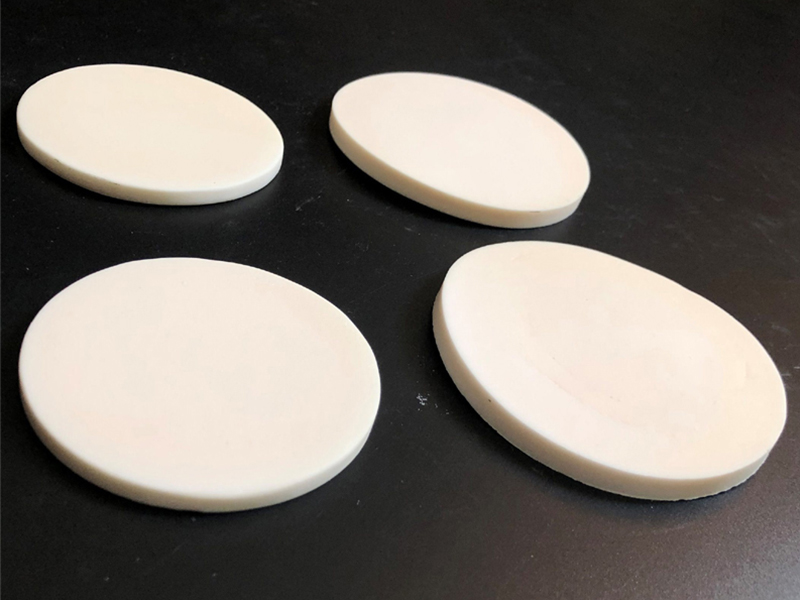

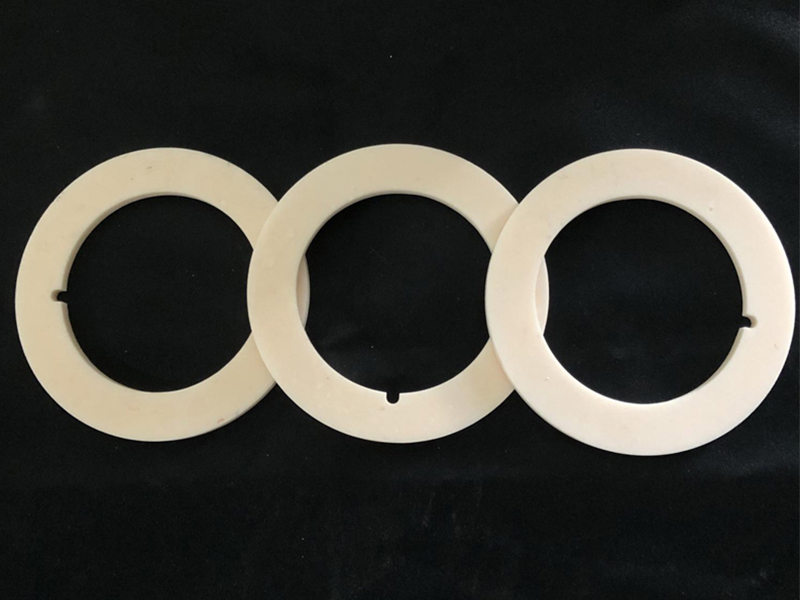

1. Alumina ceramic parts composed primarily of aluminum oxide (Al2O3).

2. High Hardness and Wear Resistance: Alumina ceramic parts are renowned for their hardness, ranking just below diamond on the Mohs scale.

3. Thermal Stability: With a melting point exceeding 2000°C, alumina ceramic parts maintain their structural integrity at high temperatures.

4. Electrical Insulation: Alumina ceramic parts are excellent electrical insulators, making them suitable for use in electronic and electrical applications.

5. Corrosion Resistance: The chemical inertness of alumina ceramic parts ensures resistance to corrosion from acids, alkalis, and other harsh chemicals, which is beneficial in chemical processing industries.

6. Biocompatibility: Alumina ceramic parts are biocompatible, meaning they can be used in medical and dental applications without adverse reactions.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search