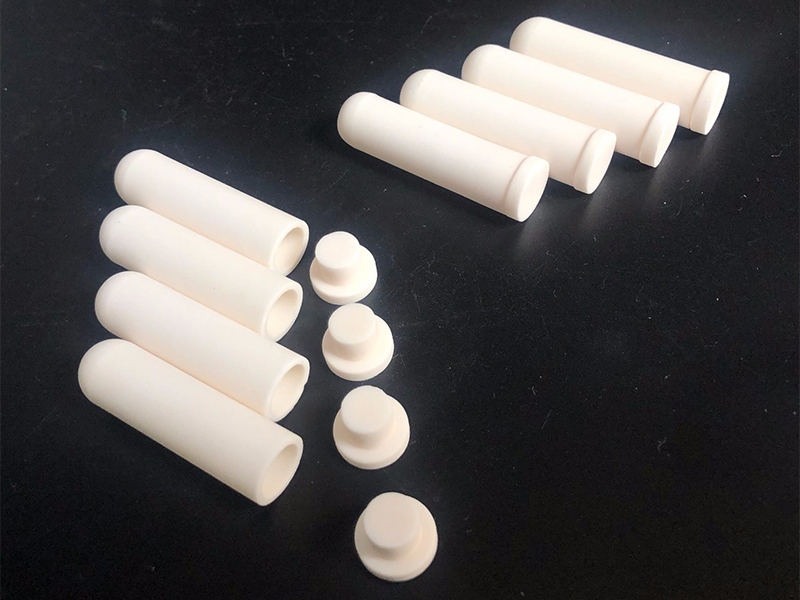

1.Alumina industrial ceramic tube have excellent wear resistance and long service life.

2.Alumina industrial ceramic tube have a smooth surface and low friction coefficient.

3.Alumina industrial ceramic tube have low volume density and light weight.

4.Alumina industrial ceramic tube can resist corrosion from various acids, alkalis, and salts, with a hardness second only to diamonds.

5.The thermal expansion coefficient and thermal conductivity of alumina industrial ceramic tube are low, and the working temperature can reach 1700 ℃.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search