1. High Thermal Resistance: Alumina crucibles with lids offer excellent thermal stability, allowing them to withstand extreme temperatures up to 1800°C without deforming or breaking.

2. Corrosion Resistance: Alumina crucibles with lids is highly resistant to chemical corrosion, making the crucible ideal for use in harsh chemical environments, where it resists attack from acids, alkalis, and other corrosive substances.

3. Durability: The high mechanical strength of alumina crucibles with lids ensures that the crucible and its lid are durable and resistant to thermal shock, maintaining integrity even during rapid temperature changes

4. High Purity: Made from high-purity alumina, the alumina crucibles with lids minimizes contamination in sensitive experiments, ensuring accurate results, especially in high-precision material testing and research.

5. Excellent Insulation Properties: The low thermal conductivity of alumina crucibles with lids offers effective insulation, allowing efficient heat retention within the crucible.

Send Email

More

Menu

- Home

- Products

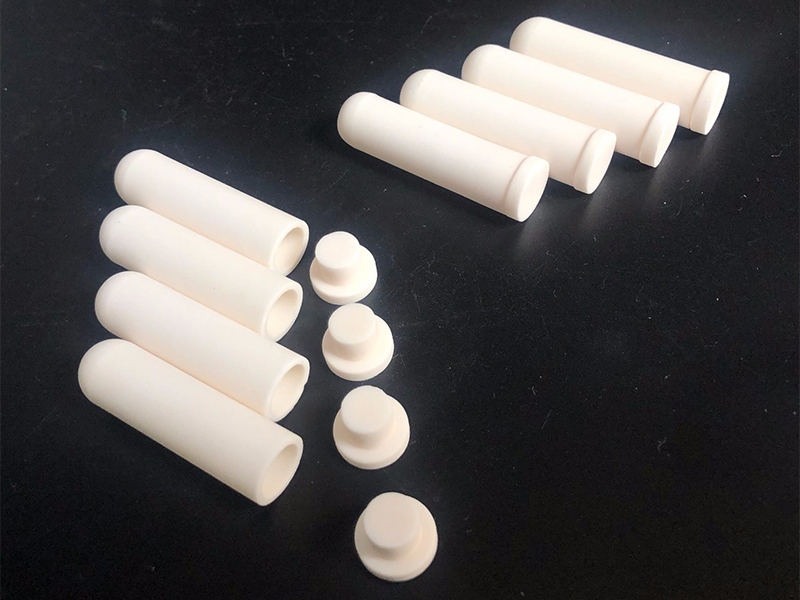

- Alumina Ceramic Tube

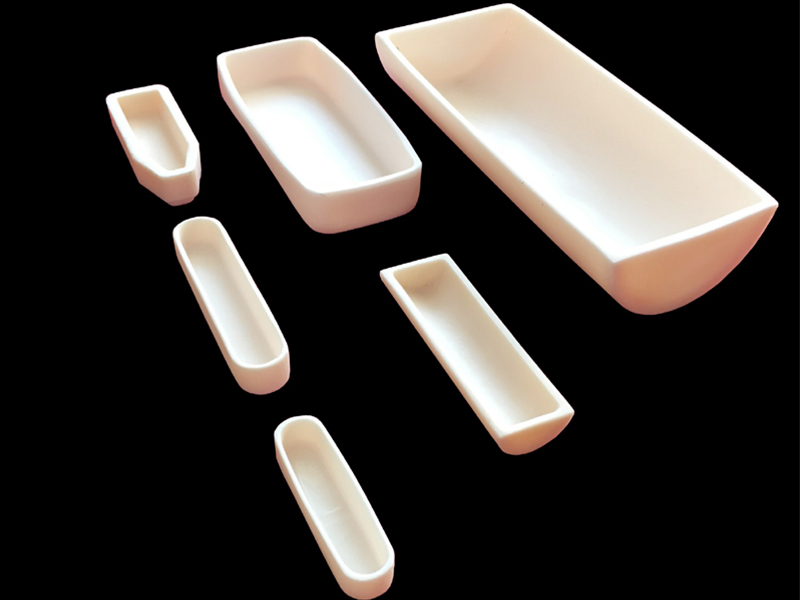

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search