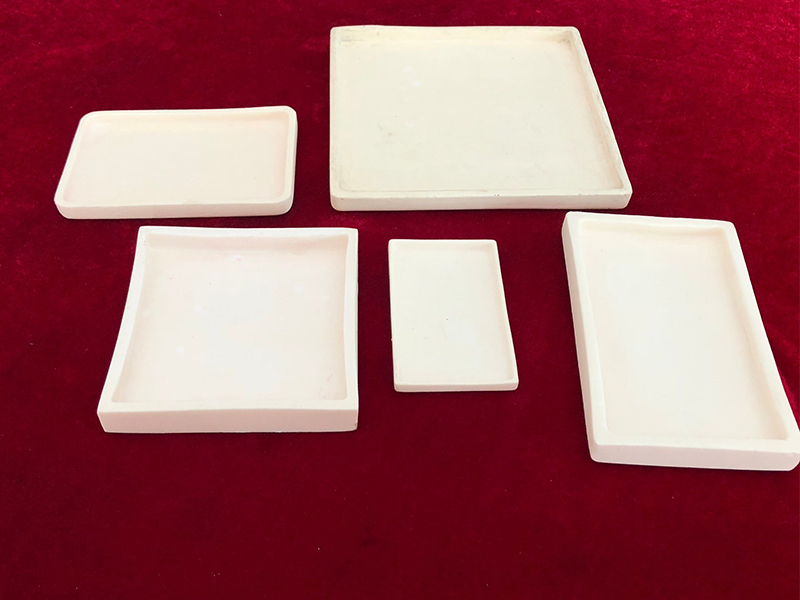

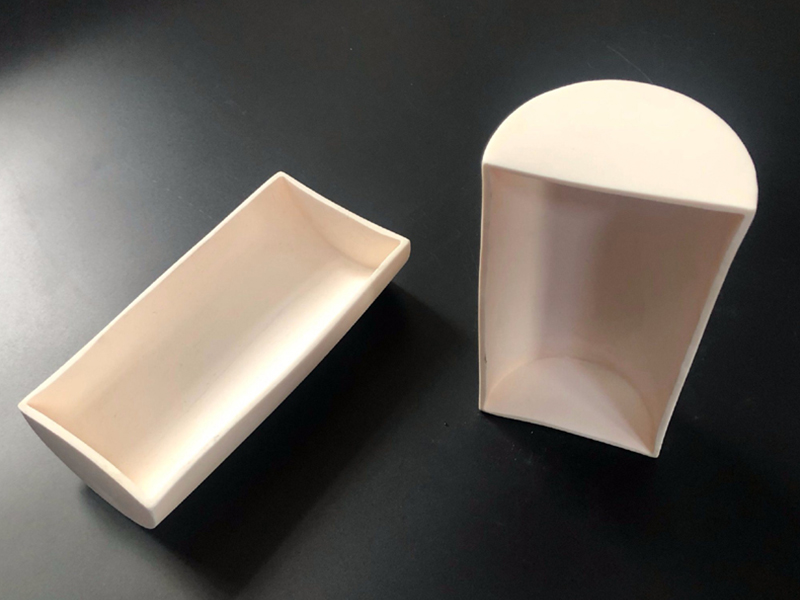

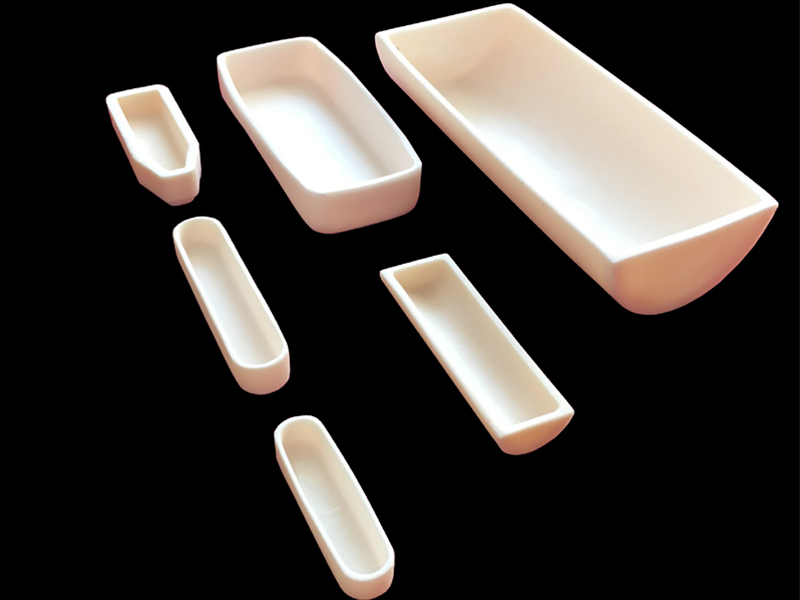

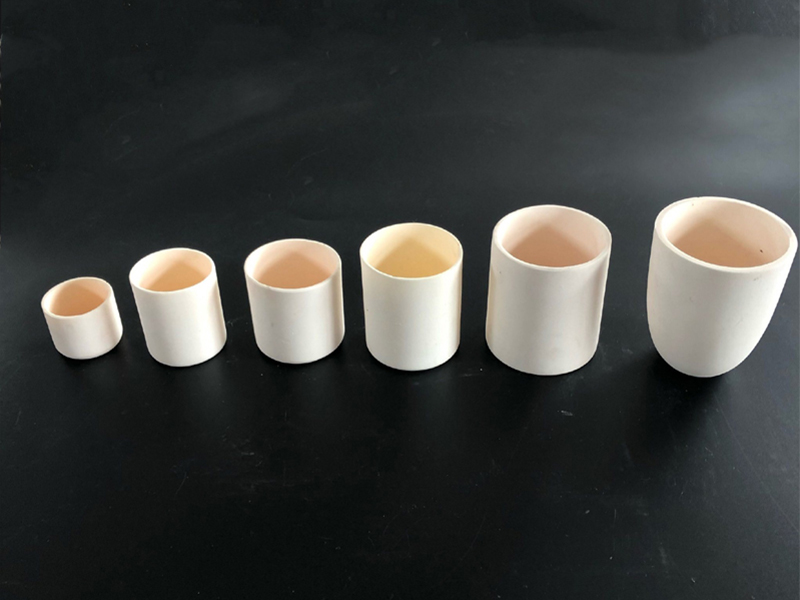

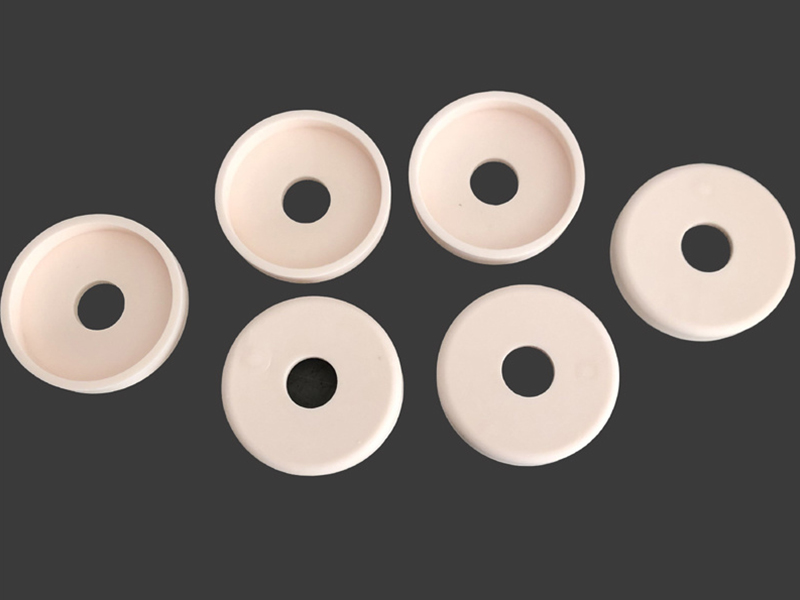

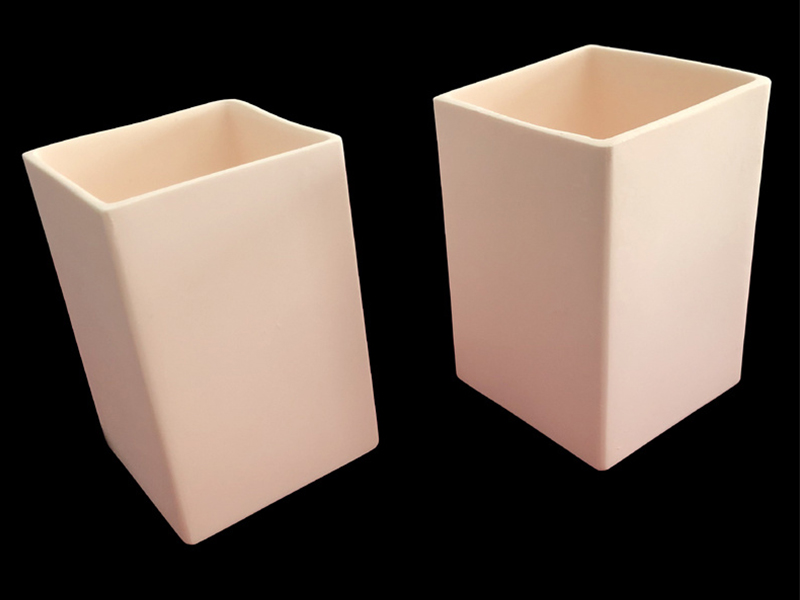

1. Alumina ceramic tray high temperature resistance, can be used for a long time below 1700 ℃, and can be used stably at 1700 ℃.

2. Alumina ceramic tray has chemical and corrosion resistance and is suitable for use in special chemical experiments.

3. Alumina ceramic tray smooth surface makes it easy to clean, ensuring that it can also be used normally over time.

4. Alumina ceramic tray wear resistance is a long-term investment for enterprises, which reduces replacement and maintenance costs.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search