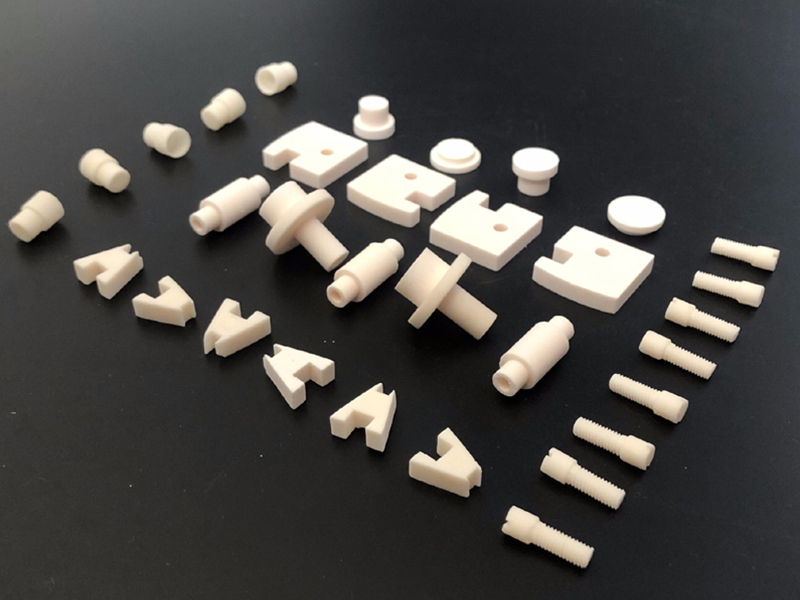

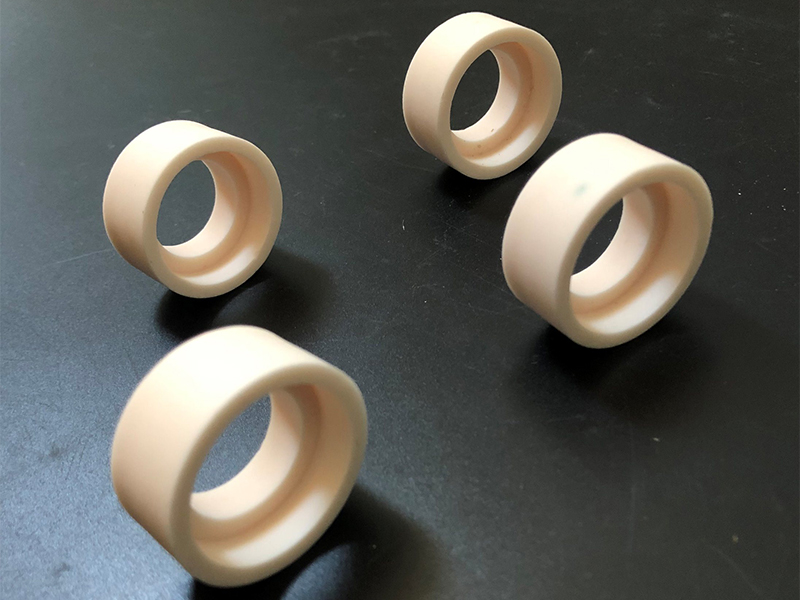

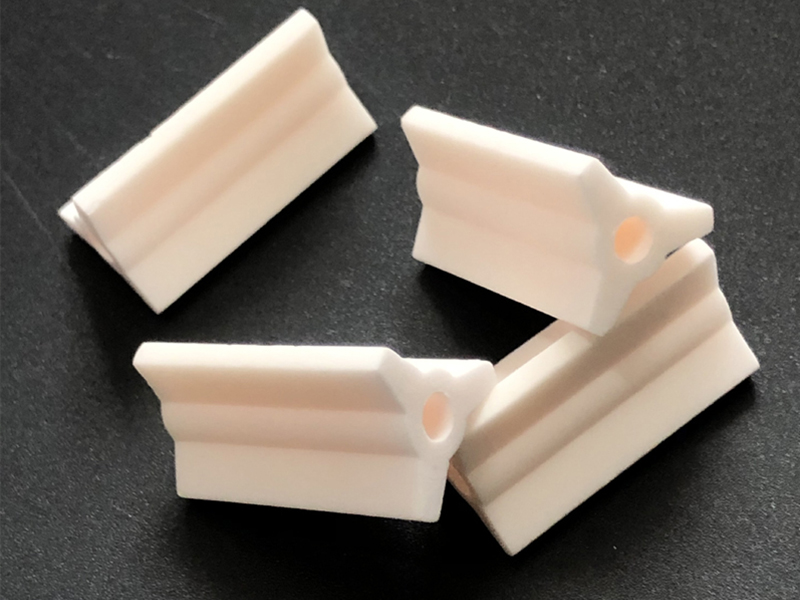

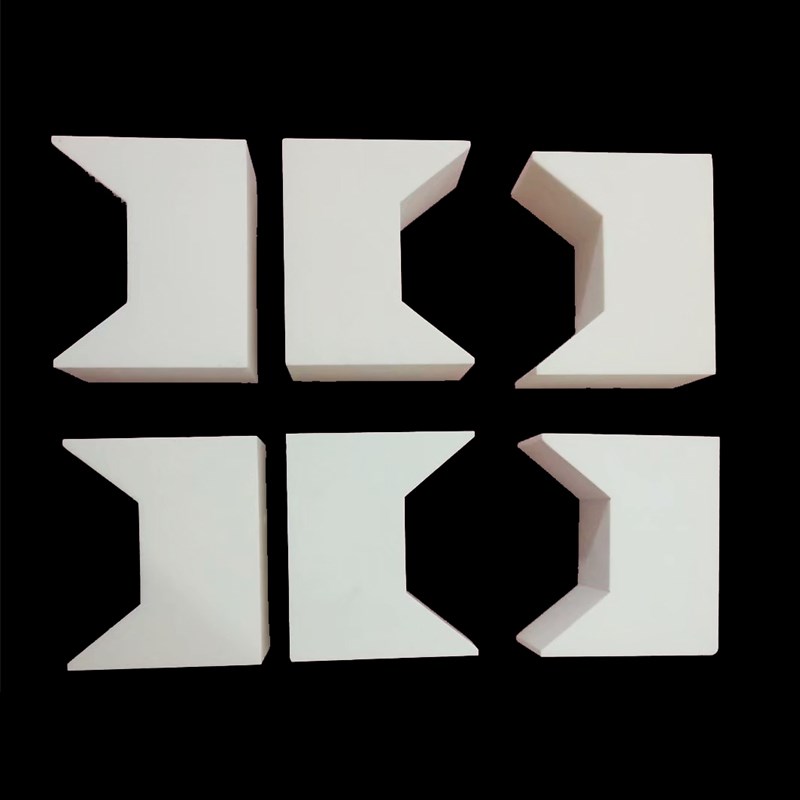

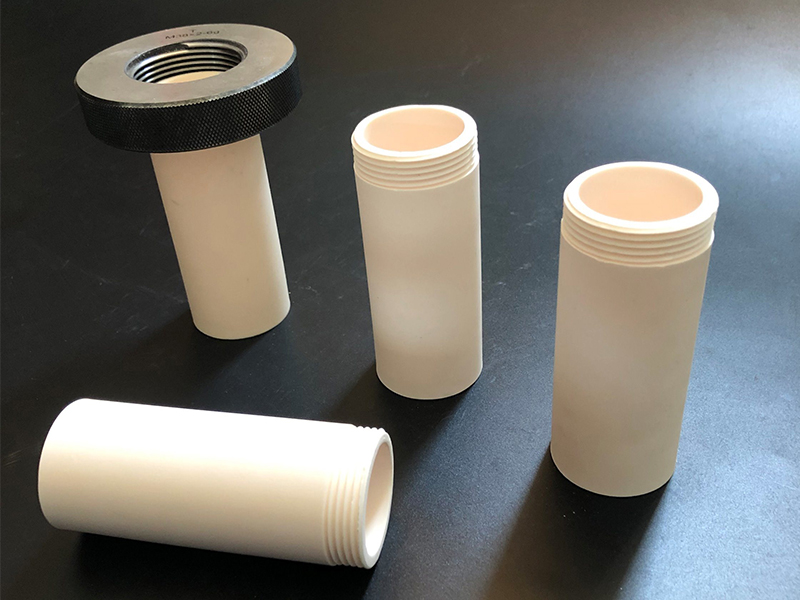

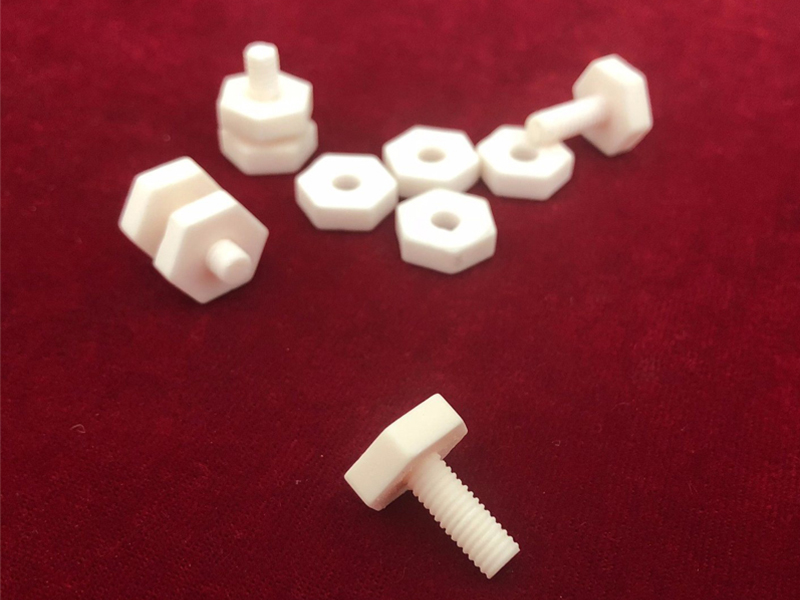

1. Alumina Ceramics Fasteners are the most highly regarded and widely used of the ceramic products.

2. It is non-conductive, resistant to corrosion, and are perfect for electrical insulation. Alumina Ceramic Fasteners has proven to be the best ceramic for protection of vital electrical components.

3. It can be processed as tubing, sheets, bars, rods, discs, and many other forms depending on the requirements of the project.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search