1. High Purity: Typically composed of over 99% alumina, ensuring minimal contamination during use.

2. Thermal Stability: With a melting point exceeding 1700°C, alumina boats can withstand extreme temperatures without deforming or melting.

3. Chemical Inertness: Resistant to most acids and alkalis, making them suitable for holding a variety of substances.

4. Mechanical Strength: Alumina's high hardness and strength make these boats durable and resistant to wear.

5. Electrical Insulation: Excellent electrical insulator, useful in environments where electrical properties are critical.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

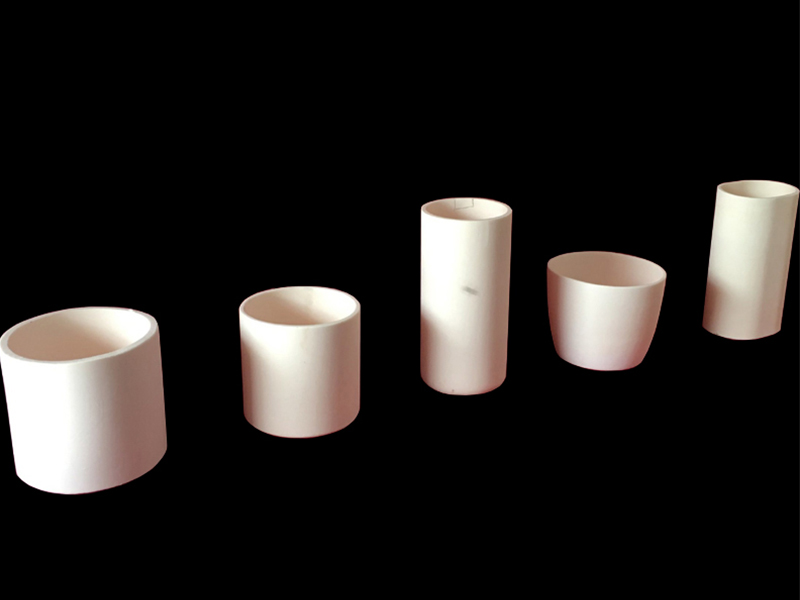

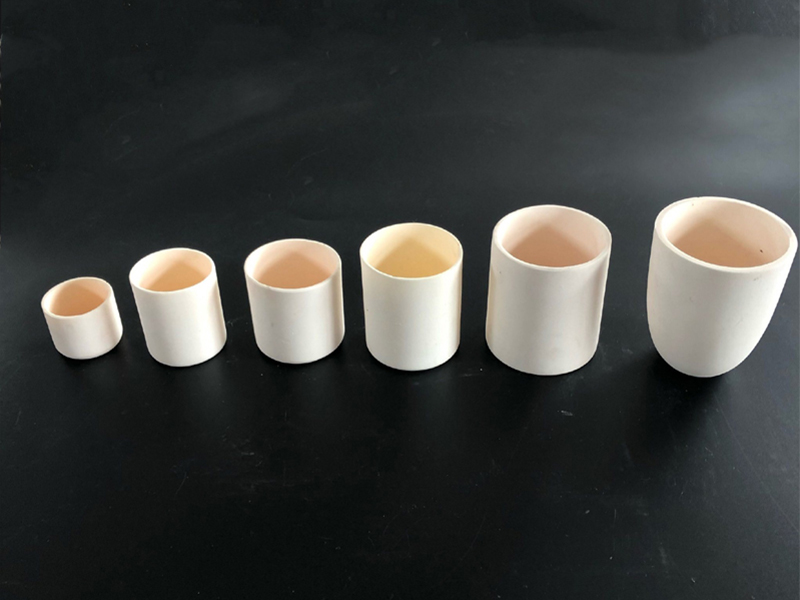

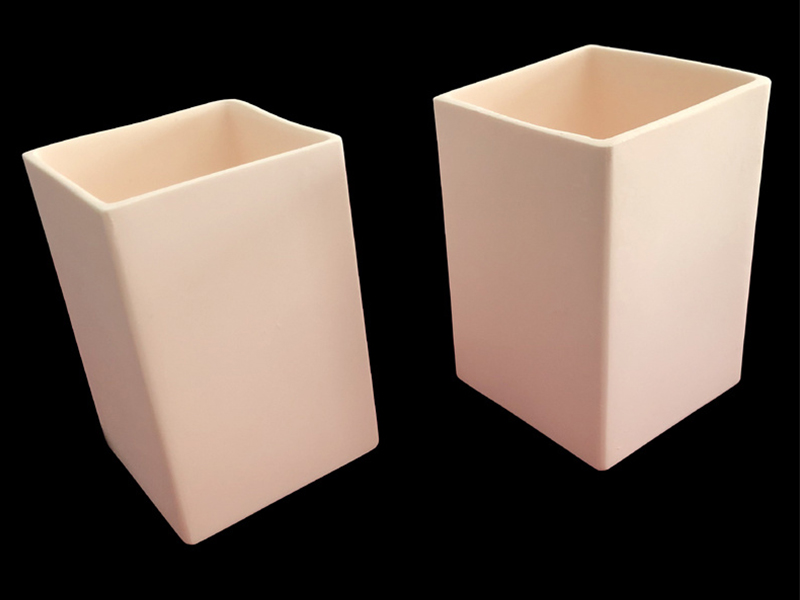

- Alumina Ceramic Crucible

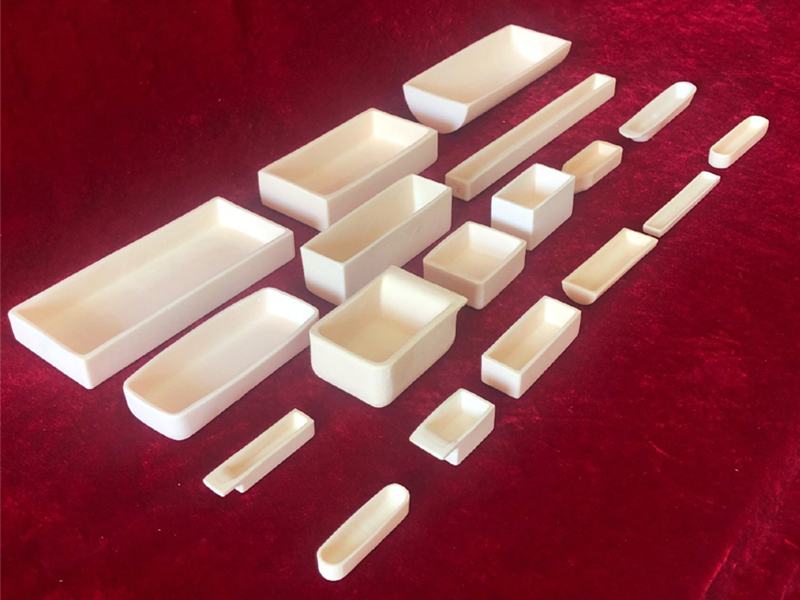

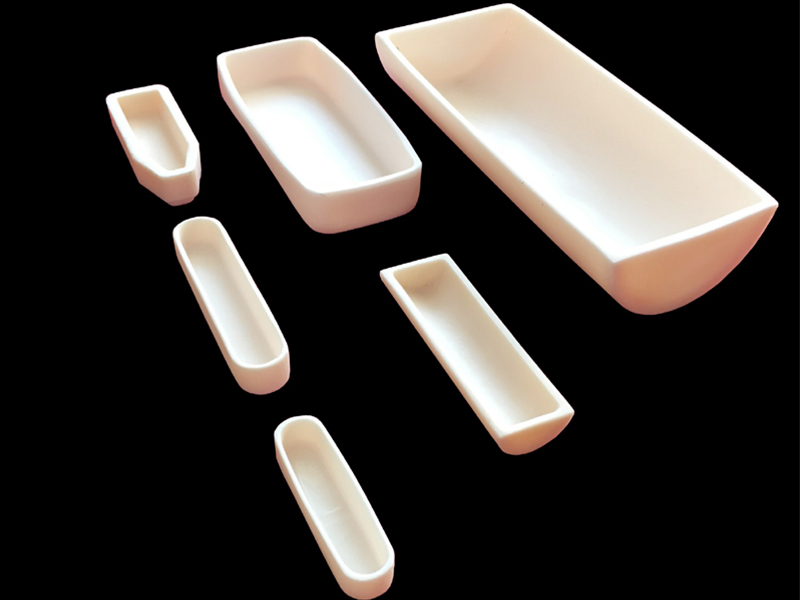

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

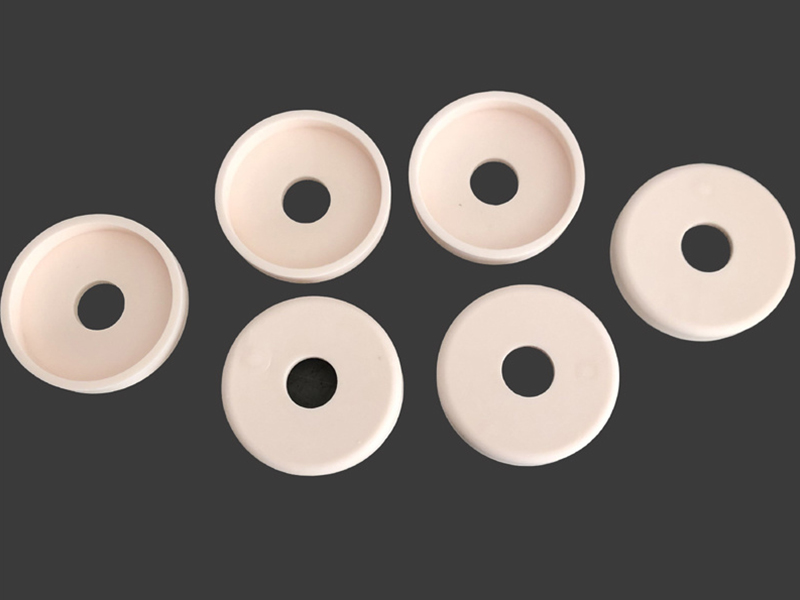

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search