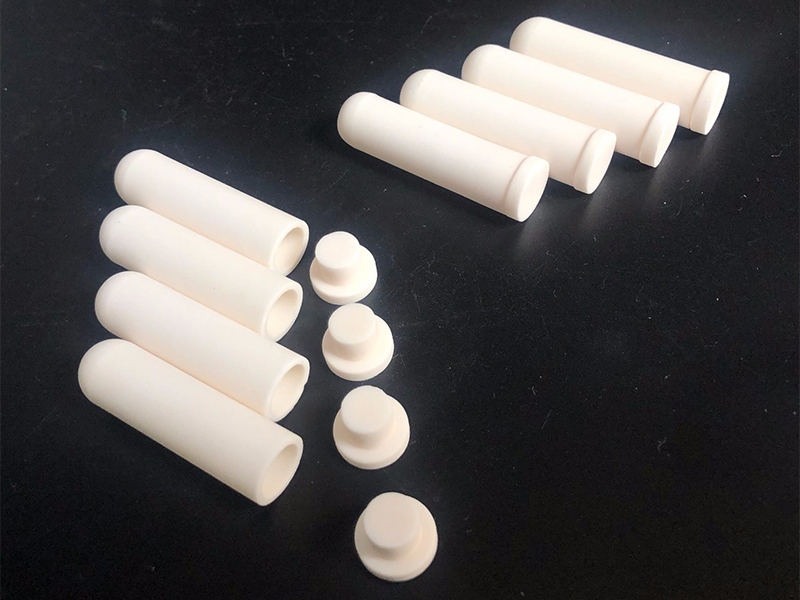

1. The high mechanical strength, wear resistance, corrosion resistance, and thermal shock resistance of alumina ceramic tube square ensure an extended service life.

2. The superior electrical insulation performance of alumina ceramic tube square makes them indispensable in electrical applications, preventing short circuits and electrical faults.

3. The chemical inertness of alumina ceramic tube square enables their safe use in corrosive chemical environments, maintaining the integrity of the product.

4. Alumina ceramic tube square have significant heat resistance and maintain structural integrity at high temperatures.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search