1. High Temperature Resistance: Cylindrical crucibles, especially those made from alumina, can withstand extremely high temperatures, making them ideal for use in high-temperature environments such as furnaces and kilns.

2. Chemical Inertness: Alumina ceramic cylindrical crucibles exhibit excellent resistance to chemical reactions with most materials, ensuring the purity of the substances being processed. This makes them suitable for use in environments where chemical reactions must be minimized.

3. Mechanical Strength: Alumina ceramic cylindrical crucibles have a strong mechanical structure, providing durability and longevity even under harsh conditions. Their robust design reduces the risk of cracking or breaking during thermal cycling or mechanical handling.

4. Thermal Shock Resistance: The ability of alumina ceramic cylindrical crucibles to endure rapid temperature changes without cracking enhances their reliability in processes that involve frequent heating and cooling cycles.

5. Dimensional Stability: Alumina ceramic cylindrical crucibles maintain their shape and integrity under high temperatures, ensuring consistent performance and accuracy in experiments or industrial processes.

Send Email

More

Menu

- Home

- Products

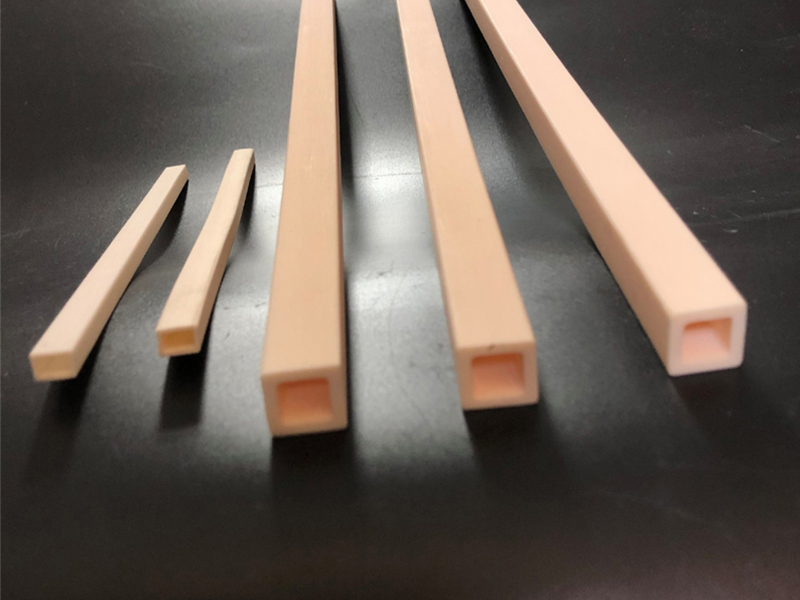

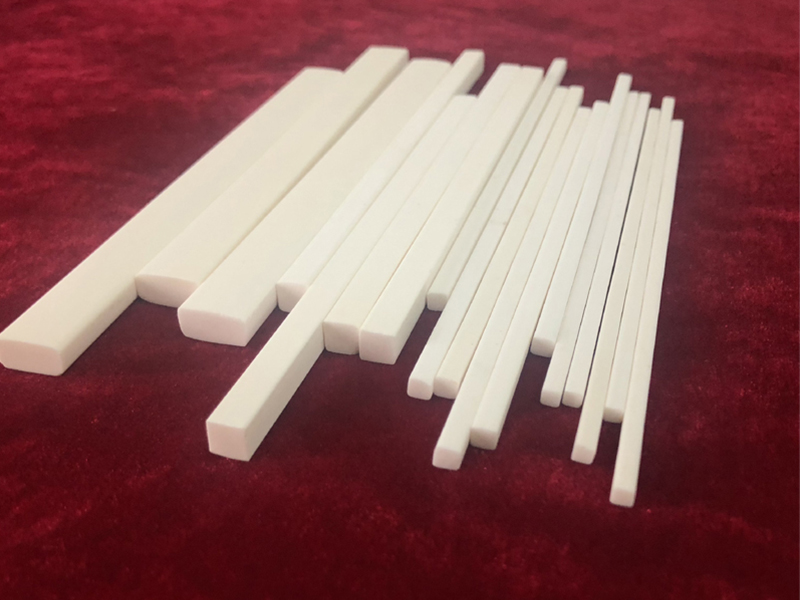

- Alumina Ceramic Tube

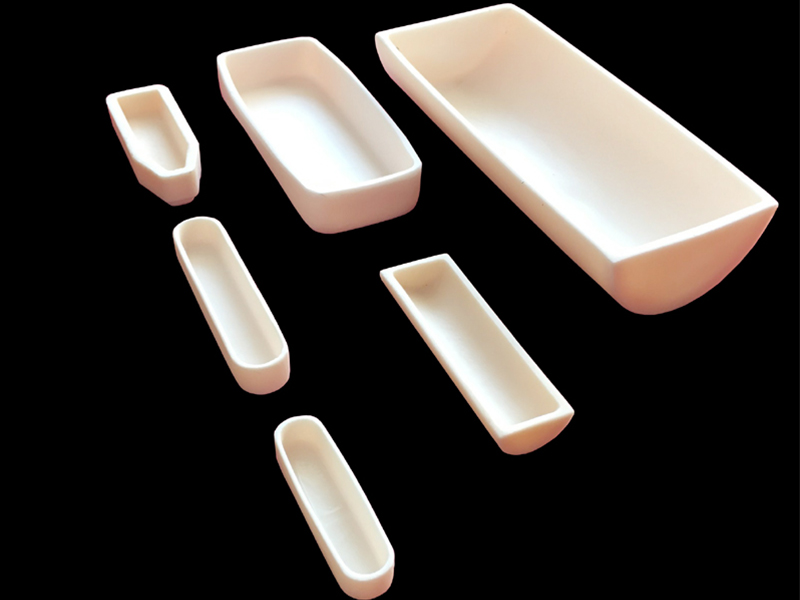

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search