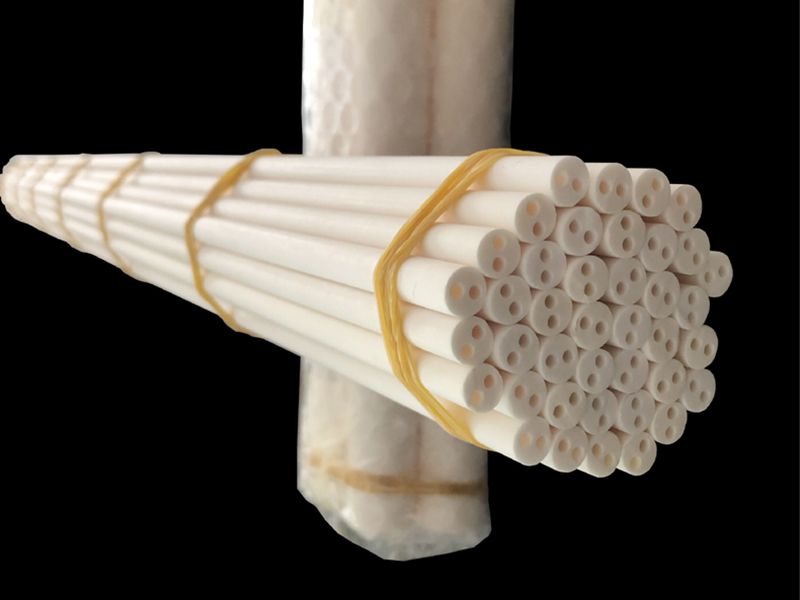

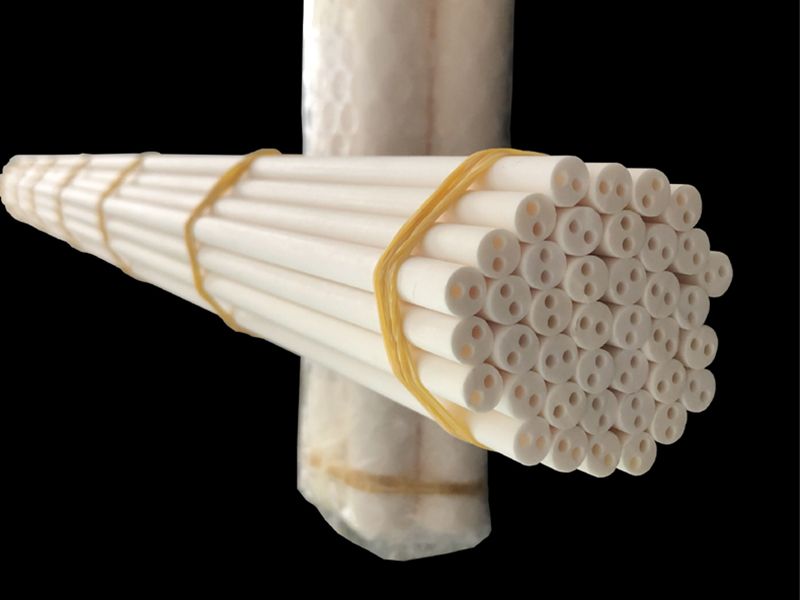

1. High Temperature Resistance: Alumina ceramic porous tubes can withstand extreme temperatures, making them suitable for environments where thermal stability is crucial.

2. Chemical Inertness: They are chemically inert, meaning they do not react with most chemicals. This property is essential in applications involving corrosive substances or harsh environments.

3. Mechanical Strength: Despite their porosity, alumina ceramic porous tubes maintain excellent mechanical strength, ensuring durability and reliability in demanding conditions.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search