1. High heat resistance: Alumina crucibles can withstand extremely high temperatures, typically up to 1700 ° C, without degradation.

2. Excellent chemical stability: Alumina crucibles can resist reactions with most acids, bases, and gases even at high temperatures. This characteristic ensures the purity of the processed material inside the crucible.

3. Excellent mechanical strength: Alumina crucibles have excellent mechanical strength and toughness, which enhances their durability and enables them to resist thermal shock and mechanical stress.

4. High corrosion resistance: Alumina crucibles are highly resistant to corrosion from molten metals, salts, and slag, making them an ideal choice for metal melting and refining applications.

5. Electrical insulation: Alumina crucibles have high electrical resistivity.

6. Low thermal expansion: Alumina crucibles have a low coefficient of thermal expansion, which can minimize the risk of cracking or deformation under extreme temperature changes, thereby improving their lifespan and reliability.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

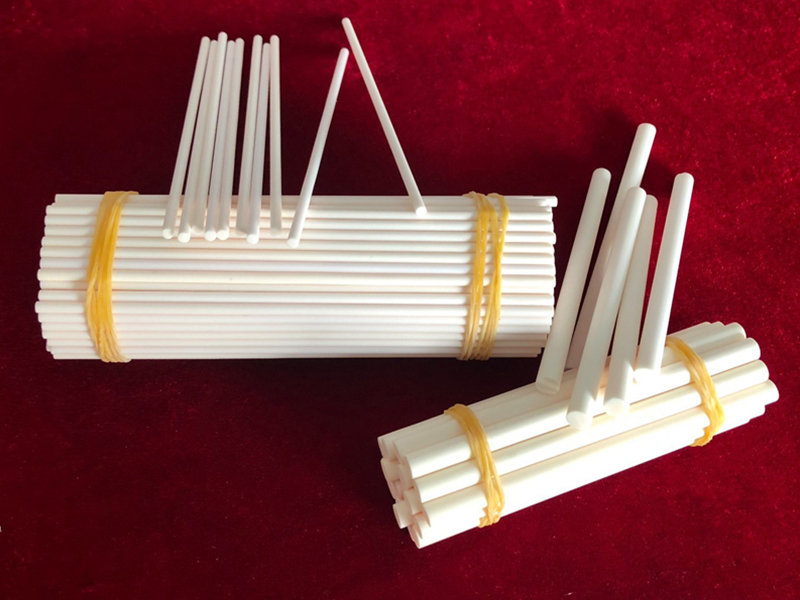

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search