1. Alumina ceramic pipe are made of high-purity aluminum oxide and are suitable for extreme environments.

2. Alumina ceramic pipes have high temperature resistance, corrosion resistance, and wear resistance.

3. The excellent mechanical strength and thermal stability of alumina ceramic pipes ensure extended service life and reduced maintenance costs.

4. From conveying abrasives to corrosive fluids, alumina ceramic pipes provide reliable performance, improving operational efficiency and productivity.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

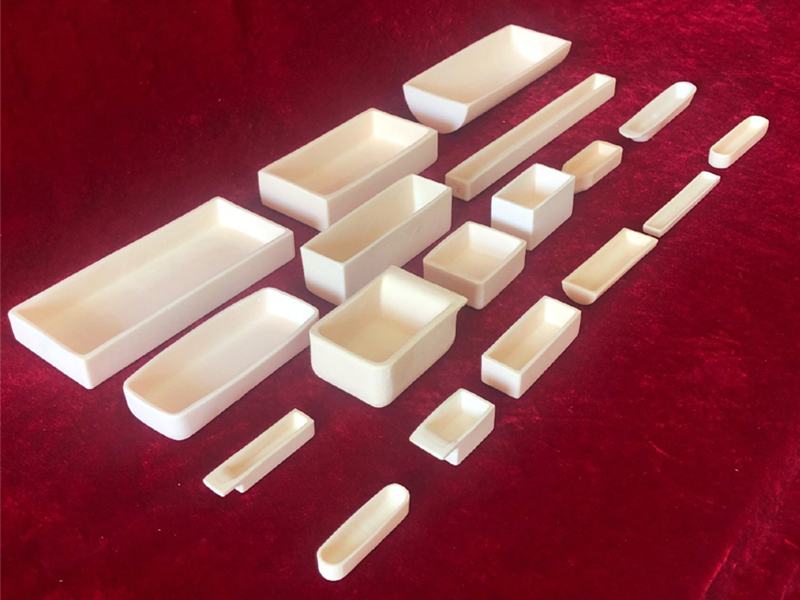

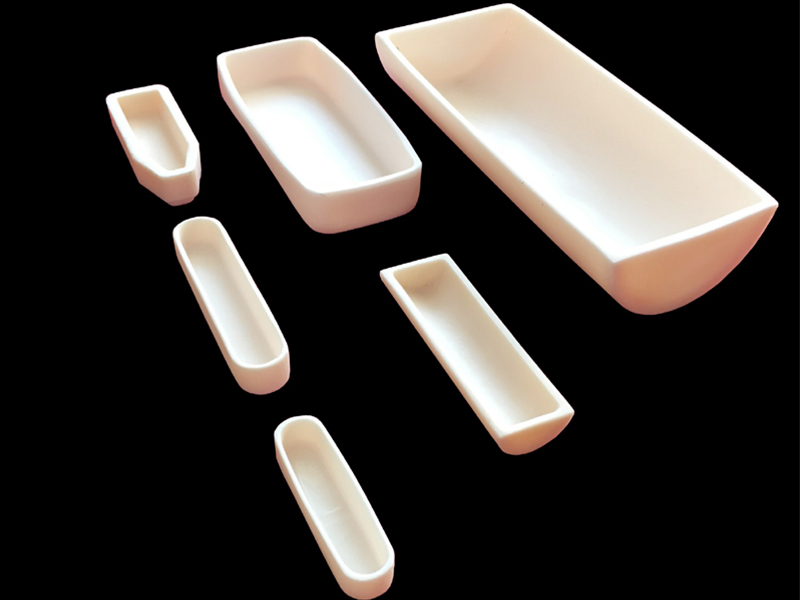

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

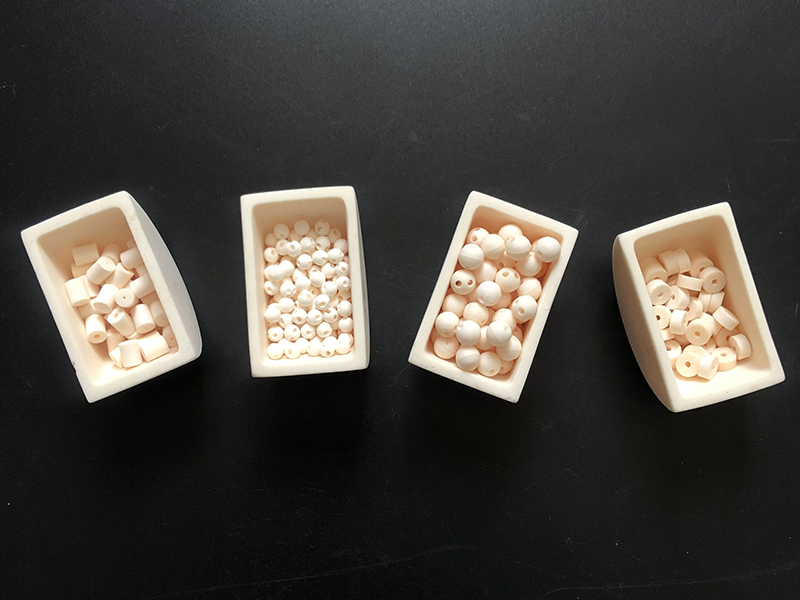

- Alumina Ceramic Beads

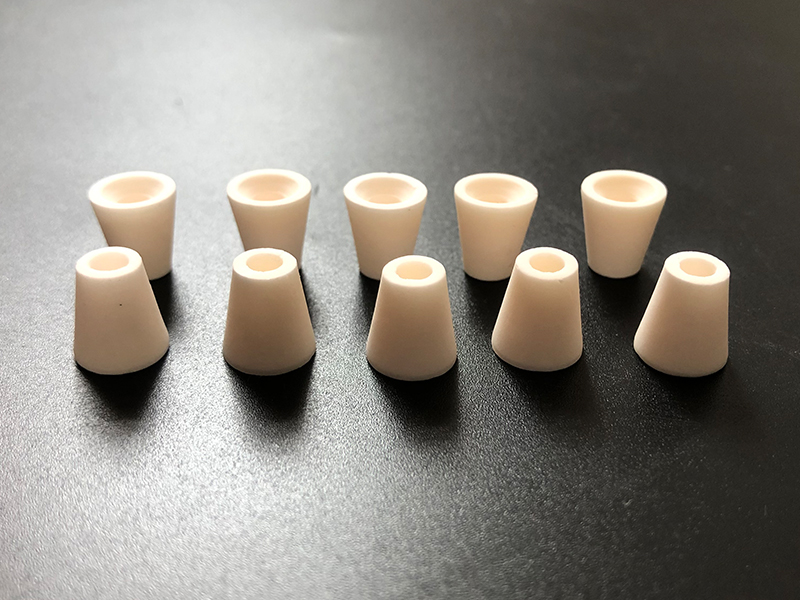

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search