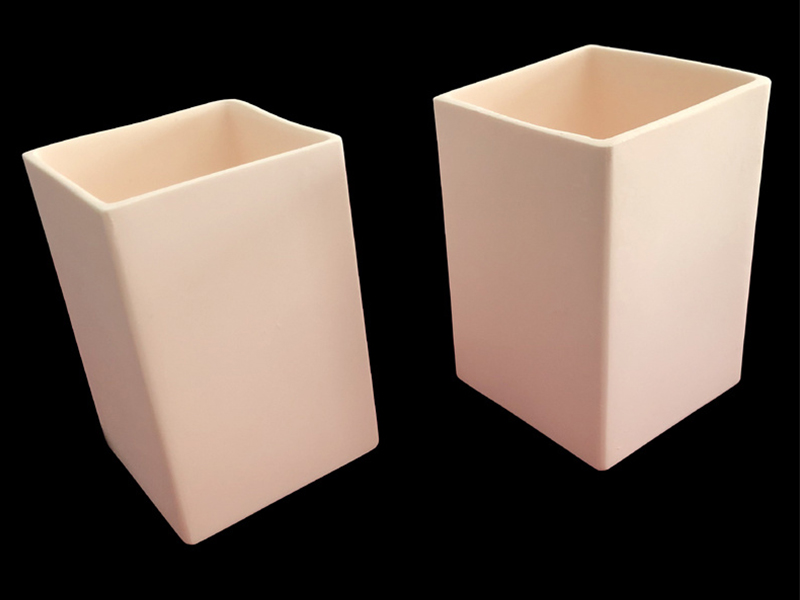

1. High Thermal Stability: Alumina ceramic crucibles can endure temperatures up to 1800°C, allowing for high-temperature experiments and processes without the risk of melting or thermal degradation.

2. Corrosion Resistance: The inert nature of alumina provides excellent resistance to chemical corrosion, ensuring that the crucibles remain unaffected by acids, alkalis, and other reactive substances commonly used in laboratories.

3. Mechanical Strength: The robust structure of alumina ceramics crucible ensures durability and resistance to mechanical stress, reducing the likelihood of cracking or breaking during handling and use.

4. Purity and Chemical Inertness: With a purity level typically above 99%, alumina ceramic crucibles offer a contaminant-free environment, crucial for precise and accurate chemical analysis.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

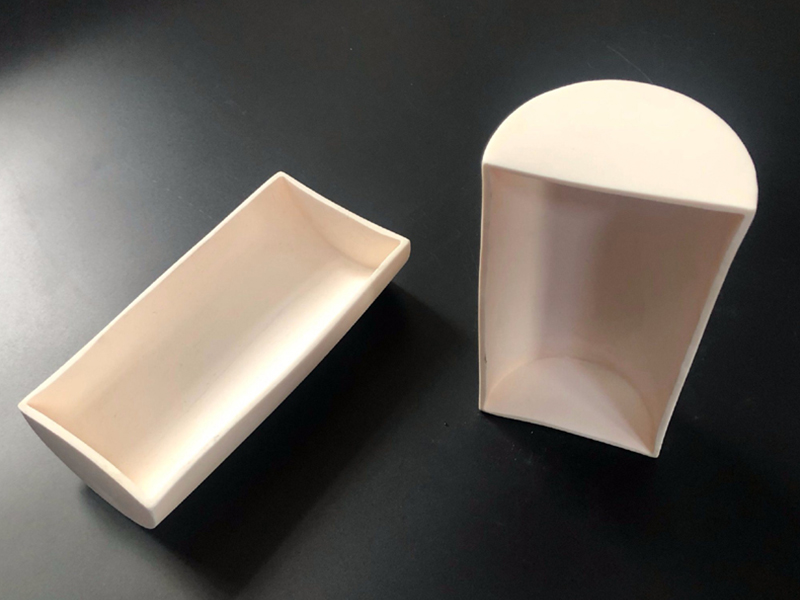

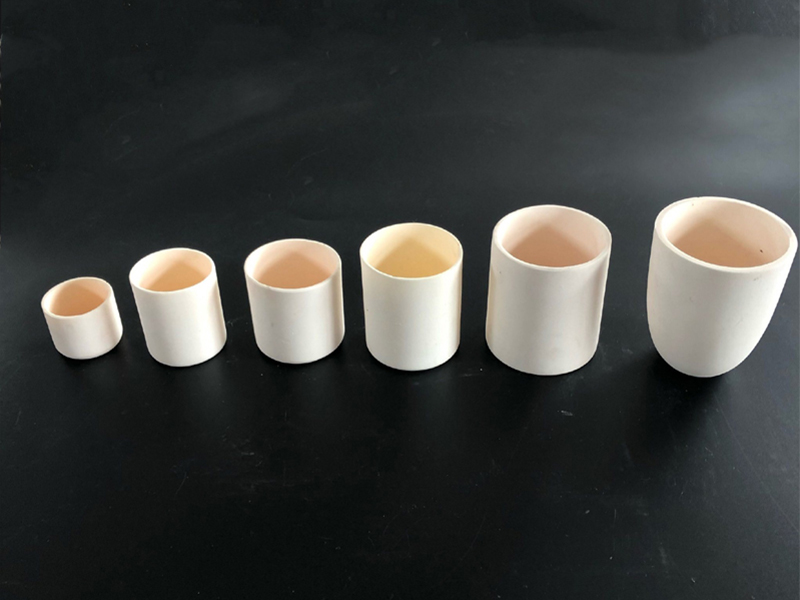

- Alumina Ceramic Crucible

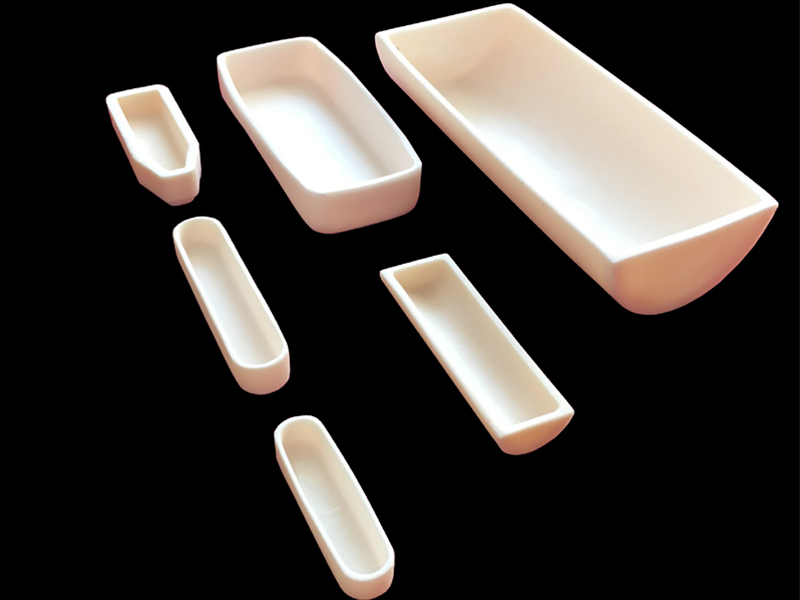

- Alumina Rectangular Trays

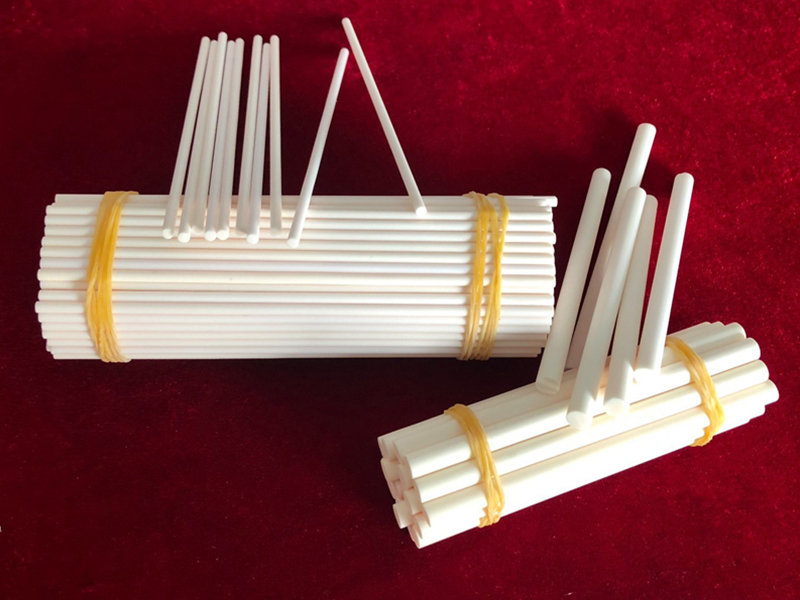

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

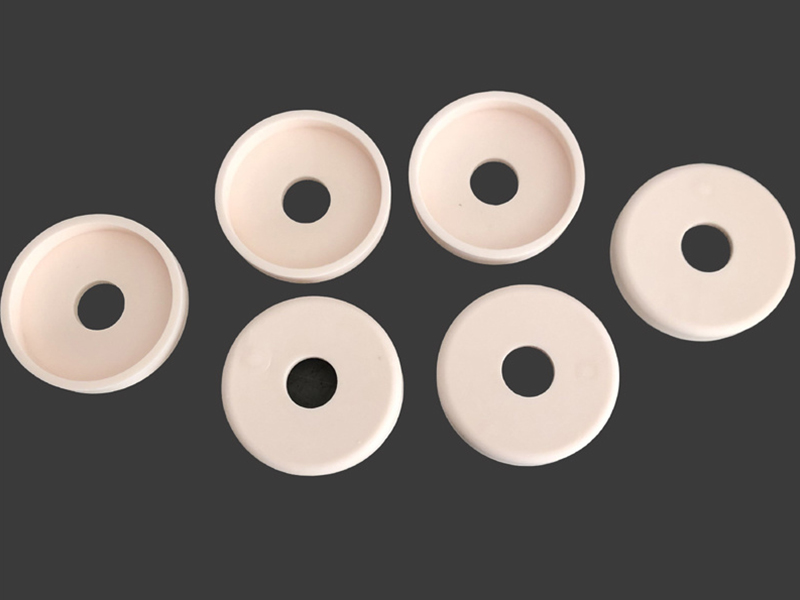

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search