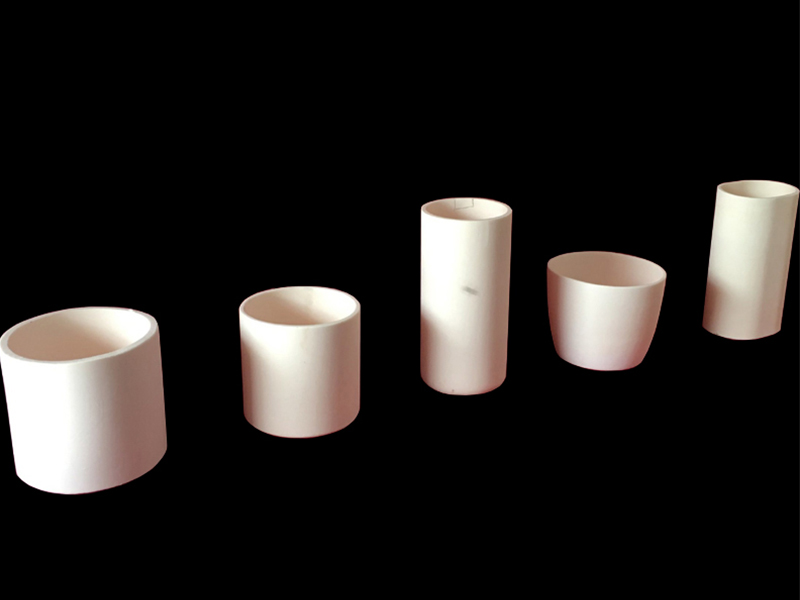

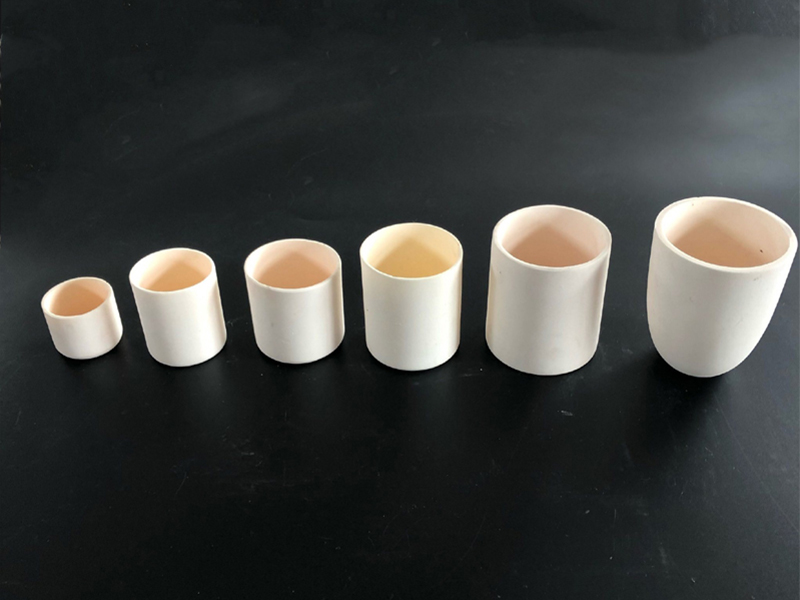

1. Aluminum Oxide Ceramic Crucibles are made of high-purity aluminum oxide, with an aluminum oxide content greater than 99%

2. Aluminum Oxide Ceramic Crucibles are resistant to chemical corrosion

3. Aluminum Oxide Ceramic Crucibles are resistant to high temperatures and can be used normally at 1600 ℃ and short-term at 1800 ℃

4. Aluminum Oxide Ceramic Crucibles are resistant to sudden cold and heat, and are not easy to explode

5. Aluminum Oxide Ceramic Crucibles are formed by slip casting molding with high density

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

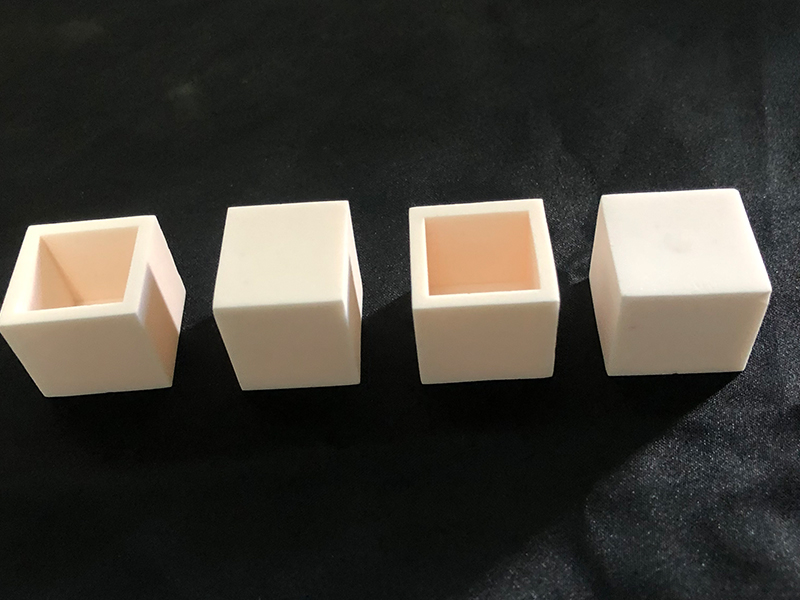

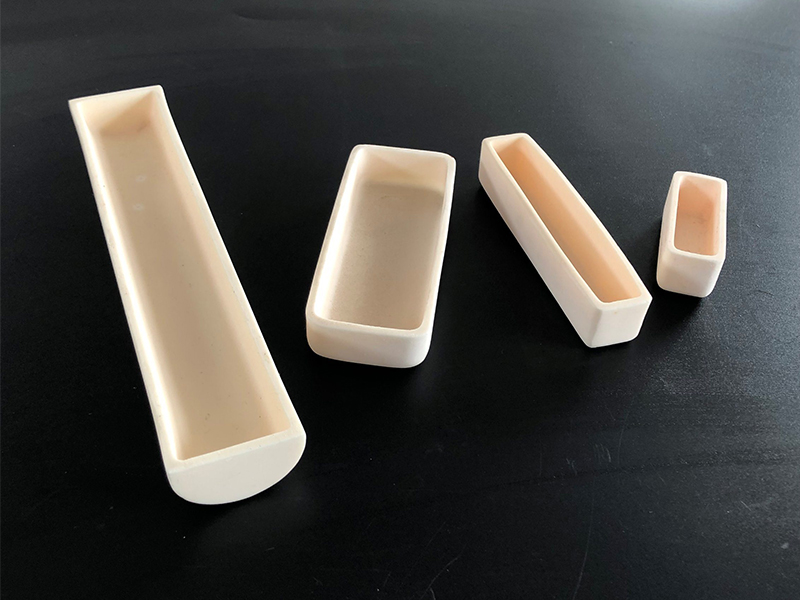

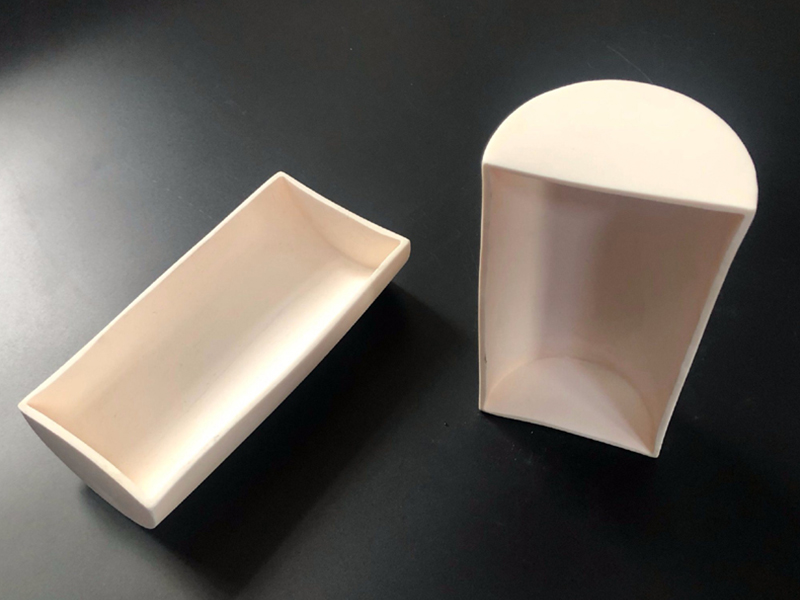

- Alumina Ceramic Crucible

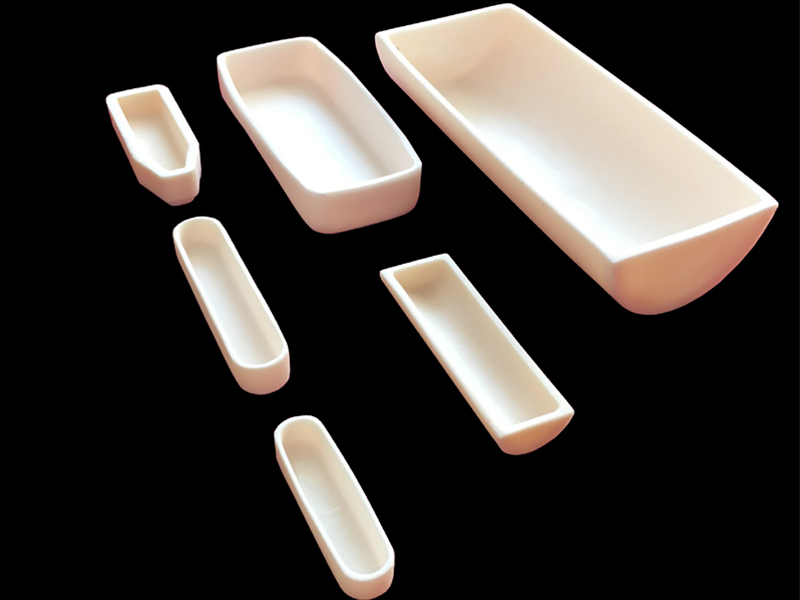

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search