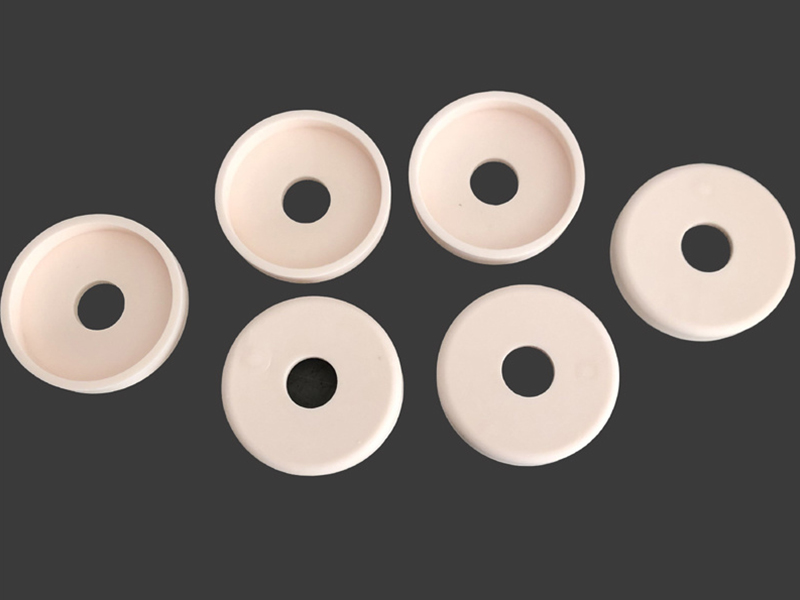

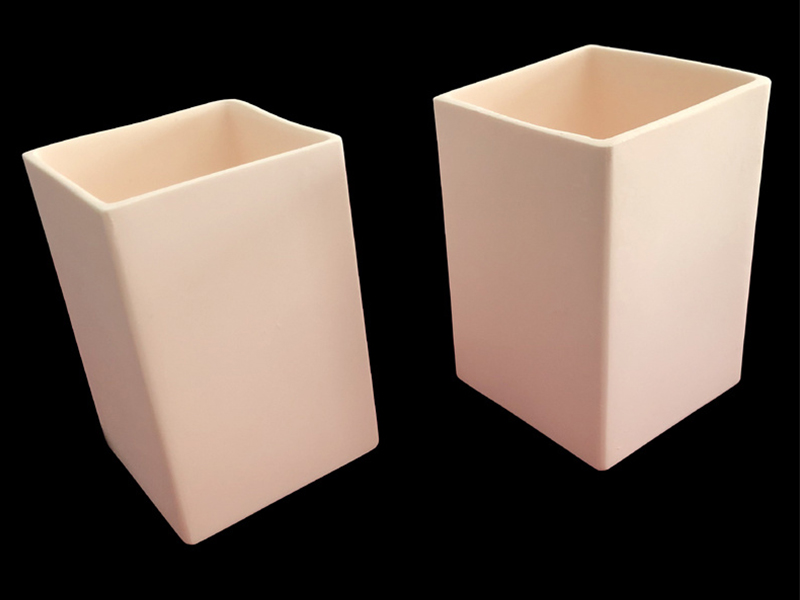

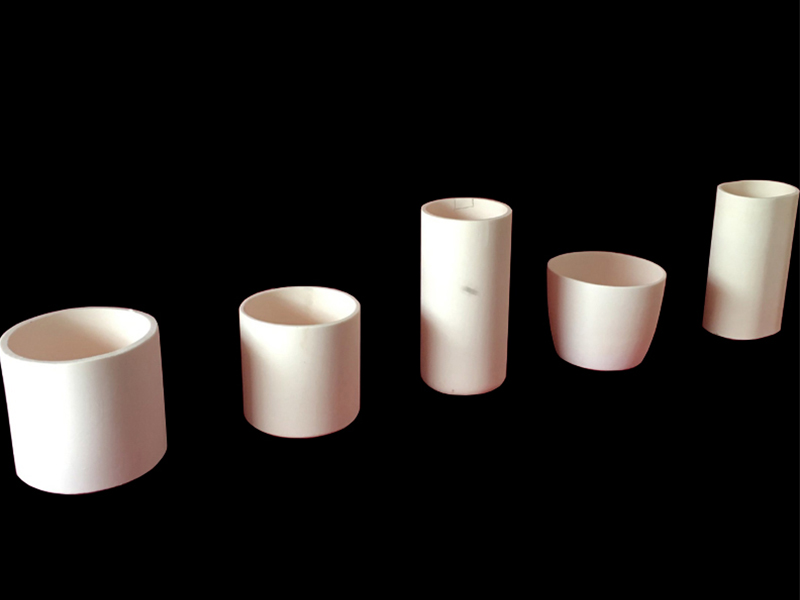

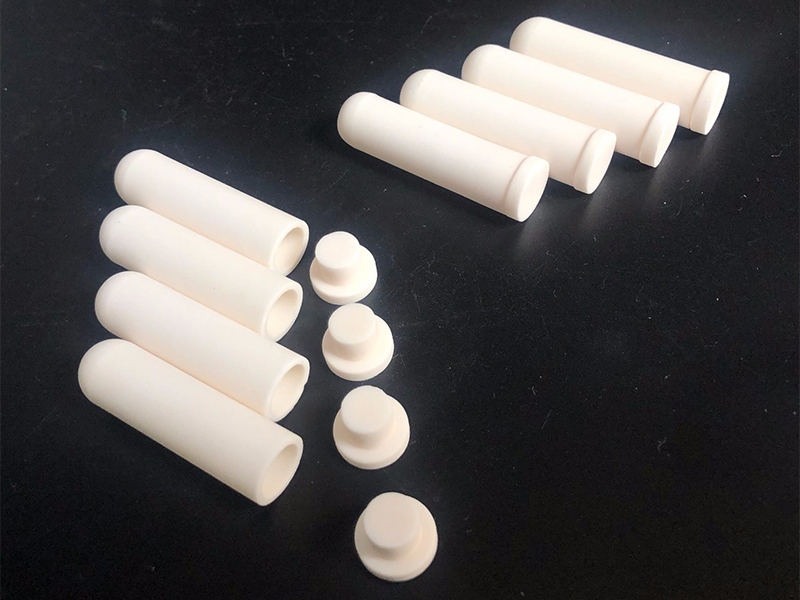

1. Alumina Ceramic Crucible Cover is mainly made of alumina.

2. Alumina Ceramic Crucible Cover is fired at high temperature with a special formula.

3. Alumina Ceramic Crucible Cover is a refractory with high fire resistance. It can withstand temperatures of 1800 degrees Celsius and high temperature resistance.

4. Alumina Ceramic Crucible Cover is usually used for smelting precious metals, nickel And other metals, with excellent chemical resistance and high temperature resistance.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search